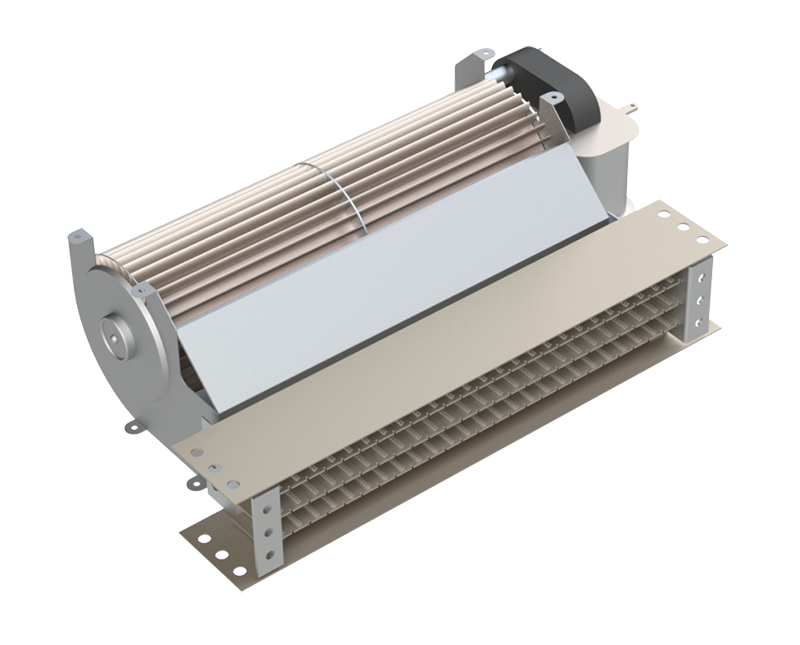

Crossflow Blower Heaters

High-Performance Crossflow Heaters Heaters for Tangential Fan and Squirrel-Cage Applications

Maximum output temperature 662ºF / 350ºC

Single or dual wattage / dual voltage options

Multiple standard lengths UL recognized

Applications: ideal for air curtains, specialty HVAC systems, decorative fireplaces, industrial dryers, dehumidification, and appliances requiring uniform, wide, forced-air heating.

TUTCO Farnam Crossflow Blower Heaters are engineered to deliver efficient, even heat across the full width of tangential (crossflow) blowers and squirrel-cage fans. Designed for applications where uniform airflow is critical, these heaters are commonly used in air curtains, HVAC systems, electric fireplaces, industrial dryers, dehumidifiers, and a wide variety of heating appliances.

Unlike traditional duct heaters, our crossflow units mount directly to the blower exhaust, providing maximum heat transfer with minimal pressure drop and a compact design. Available in multiple standard lengths and customizable wattages and voltages, these heaters give OEMs and system designers the flexibility to achieve consistent, safe, and reliable forced-air heating.

Built for industrial and commercial durability, each unit is UL recognized. With low thermal mass, these heaters heat quickly, maintain even temperatures, and eliminate hotspots, improving overall system efficiency. Whether you are developing high-efficiency air curtains, wide-slot appliances, or controlled-temperature industrial dryers, TUTCO Farnam crossflow heaters deliver dependable performance every time.

| LENGTH | MAX WATT | MAX INLET | MAX EXHAUST |

| 5.55" | 1500 W | 290º F | 662ºF |

| 7.91" | 2250 W | 290ºF | 662ºF |

| 10.32" | 3500 W | 290ºF | 662ºF |

| 12.72" | 4500 W | 290ºF | 662ºF |

| 14.98" | 5000 W | 290ºF | 662ºF |

Key Features and Benefits

- Attaches directly to blower exhaust — no extra ducts or adapters needed. Extra mounting holes allow heater to function as standalone duct heater.

- Customizable Sizes & Wattages – Offers standard lengths (5", 7", 10", 12", 15") and ability to tailor size, wattage, and voltage to your system.

- Single / Dual Wattage & Dual Voltage – Flexibility to drive different heating modes or redundancy.

- Over-temperature Protection – Integrated thermal fuses and hi-limit thermostats safeguard against runaway heating.

- High Temperature Capabilities – Capable of withstanding exhaust temperatures up to 662 °F (max) and inlet temps up to ~290 °F.

- UL Recognized Component – Ensures compliance with industrial, HVAC, and safety standards.

- Low Thermal Mass & Fast Response – Heaters heat quickly when blower is active, minimizing overshoot or delays.

- Heavy-duty Construction – Designed for reliable operation in industrial, commercial, and appliance environments.

Resources

Additional Information

| THERMOSTAT | OVERTEMPERATURE CUTOUT |

| X | No Thermostat |

| 1A | 65°C (149°F) |

| 1B | 70°C (158°F) |

| 1C | 80°C (176°F) |

| 1D | 85°C (185°F) |

| 1E | 90°C (194°F) |

| 1F | 100°C (212°F) |

| 1G | 120°C (248°F) |

| 1H | 130°C (266°F) |

| 1J | 150°C (302°F) |

| THERMAL FUSE | TEMPERATURE |

| X | No Fuse |

| D | 93°C (199°F) |

| F | 104°C (219°F) |

| H | 117°C (243°F) |

| K | 128°C (262°F) |

| L | 152°C (306°F) |

| N | 192°C (377°F) |

| R | 229°C (444°F) |

Applications for Crossflow Blower Heaters

Crossflow blower heaters are used wherever a wide, uniform heated air curtain, panel, or slot is needed. Typical applications include:

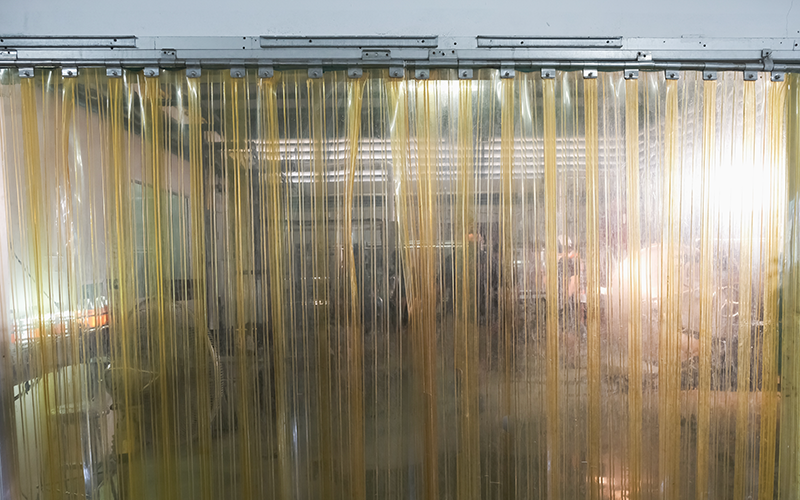

Air curtains & air doors — Crossflow and tangential heaters heat air across entrances, creating a consistent thermal barrier to maintain indoor temperature, reduce energy loss, and improve comfort. They ensure even airflow, minimizing drafts and the infiltration of dust, insects, or outdoor pollutants. READ MORE

Specialty HVAC & ventilation systems — These heaters provide auxiliary or post-heating to maintain stable, comfortable indoor environments. They supplement primary HVAC systems, respond quickly to temperature changes, improve energy efficiency, and ensure consistent air distribution.

Fireplaces & heating appliances — Integrated heaters distribute warm air evenly across openings, enhancing heat transfer and performance. This results in faster, more uniform heating and reduces cold spots.

Industrial dryers & dehumidifiers — Precision-controlled heaters maintain consistent heated airflow for drying, curing, or moisture reduction, supporting product quality and uniform temperature profiles in manufacturing, food processing, or pharmaceutical applications.

READ MORE

Appliances — From ovens and dryers to instant air heating systems, these heaters deliver reliable, rapid, and evenly distributed heat, helping designers meet performance specs while optimizing energy use and safety. Process heating — Controlled hot air is essential for equipment enclosures, assembly lines, or specialized processes. These heaters provide uniform, adjustable heating to support sensitive operations, improve efficiency, and maintain consistent process conditions. In all these uses, the heater must deliver consistent temperature rise across the full width of air, with minimal hotspots, while matching the blower’s airflow profile.

Benefits Over Alternate Solutions

Optimized airflow matching — Unlike traditional duct heaters that rely on straight airflow, TUTCO Farnam crossflow blower heaters are specifically engineered to align with the tangential blower’s wide, shallow ribbon of air. This design ensures even heat distribution across the full width of the airflow path, reducing hotspots and cold zones, improving efficiency, and enhancing overall system performance.

Compact, low-profile design — The shallow geometry of the crossflow heater allows it to fit into tight or constrained system footprints, making it ideal for space-limited applications such as appliances, industrial enclosures, and HVAC retrofit systems without sacrificing heating performance.

Direct mount simplicity — These heaters attach directly to the exhaust of the blower, eliminating the need for extra ductwork, adapters, or brackets. This not only simplifies installation but also reduces air leakage, pressure drop, and potential inefficiencies from misaligned components.

Custom design flexibility — Farnam offers both standard and fully customizable options for length, wattage, voltage, lead length, and mounting configurations. This ensures the heater can be tailored to your exact system requirements, whether for industrial machinery, air curtains, dryers, or appliances, providing OEMs and engineers with maximum design flexibility.

Integrated safety — Each heater includes built-in thermal fusing and hi-limit protection, minimizing the need for external safety devices while safeguarding the system against overheating, improving operational reliability, and enhancing compliance with safety standards.

UL recognized component — Being a UL recognized component gives system designers, engineers, and OEMs confidence that the heater meets stringent safety and quality standards, streamlining regulatory approvals and reducing liability concerns.

Proven reliability — With decades of experience in electric heating and blower integration, Farnam’s crossflow heaters are engineered for long-lasting, high-performance operation even in demanding industrial, commercial, and appliance applications. This proven reliability reduces maintenance requirements and downtime, delivering consistent heat and performance over the life of the system.

Why Choose TUTCO Farnam?

With decades of experience in electric heating and blower systems, TUTCO Farnam offers crossflow blower heaters that combine efficiency, safety, and durability. Our heaters are designed to integrate seamlessly with tangential fan systems, ensuring optimal performance in industrial, commercial, and appliance applications. Whether you need a standard CB Series unit or a custom-designed heater module, Farnam delivers the expertise and quality your system demands. Request a Quote or Contact our Applications Engineers to learn how TUTCO Farnam Crossflow Blower Heaters can improve your system performance today.

Critical Note!

The current rating specifications for the over-temperature protection devices limits the 120V versions to a maximum 1700 watts , 208V versions to 1950 watts, and 240V versions to a maximum 2250 watts. Do not specify an over-temperature cutout or thermal cutoff if higher wattages are required.

Frequently Asked Questions

The integrated thermal fuses and hi-limit thermostats provide safe operation, even in high-temperature industrial applications.

Multiple OEMs rely on these heaters in air curtain systems, industrial dryers, and appliance applications, where even heat distribution and long service life are critical.

A 10.32" CB Series heater delivers up to 3,500 W under maximum design conditions, ensuring rapid heat-up and uniform airflow heating.