Flow Torch™ 800

High-Flow, Low Pressure Drop Industrial Air Heating Solution

The Flow Torch™ 800 is TUTCO Farnam’s premier open coil air heater designed for industrial applications that demand high airflow at low pressure drop. Its innovative design minimizes flow restrictions while maximizing heat transfer efficiency, making it an ideal choice for processes that require rapid heating, precise temperature control, and large-volume airflow.

Constructed with an 8-inch diameter stainless steel body, the Flow Torch 800 offers robust durability, long-life performance, and reduced operational costs. At the core of its design is a spiral wound open coil element made from the highest-grade materials, which ensures fast heat-up and cool-down cycles while delivering maximum thermal output to your process air. Engineered for versatility, reliability, and high efficiency, the Flow Torch 800 is an excellent solution for industries ranging from chemical processing to textile manufacturing and environmental test chambers.

Flanged Fittings!

We have flanges available as a standard option on our Flow Torch heaters. Click here to build your FT400, FT600 & FT800 with flanged inlet and exhaust fittings.

| MAX WATT | MAX INLET | MAX EXHAUST | MIN SCFM | MAX SCFM | PSIG* |

| 75000 W | 250º F | 900º F | 76 | 2000 | 3 |

* with minimal leakage.

| WATTAGE | 20.0 kW | 35.0 kW | 50.0 kW | 65.0 kW | 75.0 kW |

| MIN. SCFM REQUIRED | 76.3 | 133.6 | 190.8 | 248.0 | 286.2 |

Key Features & Benefits

High Airflow Capacity with Minimal Pressure Drop

With the ability to handle up to 2000 SCFM at a maximum operating pressure of 3 PSIG, the Flow Torch 800 enables large-volume air heating with minimal resistance. This reduces energy consumption and enhances the efficiency of your air-handling system.

Rapid Thermal Response

The spiral wound open coil element allows for near-instantaneous heating and fast cooldowns. This rapid thermal response improves process control, reduces downtime, and helps maintain consistent production quality.

Wide Temperature Range

The Flow Torch 800 reaches a maximum output temperature of 482°C (900°F), with standard inlet temperatures up to 250°F and modifications available for higher inlet conditions. This flexibility accommodates a wide variety of industrial applications.

Robust Construction

The stainless steel heater body, inlet, and exhaust fittings are engineered for durability in demanding environments, offering reliable long-term performance and reduced maintenance requirements.

Customizable Power Options

Available in wattages from 2 kW to 750 kW, the Flow Torch 800 can be configured to meet specific process requirements, ensuring optimal performance for your unique application.

Optional Control Panels

Precision temperature control is available with optional control panels, allowing operators to maintain consistent process conditions and ensure optimal thermal performance.

UL Recognized Components

All Flow Torch heaters are UL recognized under UL file number E365755, providing assurance of quality, safety, and compliance with rigorous industrial standards.

Flanged Fittings

Standard flanged inlet and exhaust options simplify integration into your system. Customers can select flanged fittings for the FT400, FT600, and FT800 models to accommodate their specific duct or airflow setup.

Specifications

Mounting....................................................Horizontal / Vertical

Leads..........................................................20 AWG, 12" Long

Heater Body...............................................Stainless Steel

Air Entryway Fitting...................................Stainless Steel

Inlet Fitting................................................Stainless Steel

Exhaust Fitting...........................................Stainless Steel

*Note: Minor leakage may occur through stranded leads.

Ready to Build Your Solution?

Request a Quote or Contact our Applications Engineers to learn how a Flow Torch™ heater can improve your process consistency, energy efficiency, and thermal performance.

Applications

The Flow Torch 800 is designed to serve a wide range of industrial and manufacturing processes where controlled, high-volume heated air is essential. Its combination of high airflow, rapid response, and durable construction makes it suitable for even the most demanding operations. Typical applications include:

Hot Air Curtains – Maintain temperature separation in industrial environments, reducing energy loss and improving workspace conditions.

Air Drying – Efficiently dry products, coatings, or materials while maintaining precise temperature control.

Baking – Achieve uniform heating for baked goods, industrial coatings, or composite materials.

Chemical Processing – Provide consistent, controlled heat for chemical reactions, drying, or curing processes.

Dehumidification – Support controlled drying processes in facilities requiring regulated humidity levels.

Laminating & Coating – Ensure consistent heat for adhesives, laminates, and coatings to improve product quality.

Textile Applications – Maintain precise air temperatures for fabric drying, curing, or finishing operations.

Web & Ink Drying – Deliver high-volume heated air for printing presses or other continuous web-processing equipment.

Paint Baking/Drying – Support rapid drying of paints and coatings, reducing cycle times and increasing productivity.

Plastic Curing & Metallization – Provide stable, uniform heating for plastics, films, or metalized surfaces.

Gas Heating & Hopper Drying – Supply controlled heat for gas or material drying processes.

Sterilization – Maintain high airflow at elevated temperatures for sterilizing equipment or materials in industrial or laboratory settings.

Advantages Over Conventional Heaters

The Flow Torch 800 is engineered to outperform traditional air heating technologies, delivering benefits that improve both process efficiency and operational reliability:

High Airflow, Low Resistance – The open coil design ensures minimal pressure drop, enabling efficient high-volume heating without straining your blower or fan systems.

Fast, Precise Thermal Control – Quick heat-up and cool-down cycles allow for precise temperature management and reduce downtime between operations.

Durable, Long-Lasting Design – Stainless steel construction and high-grade coil materials provide longevity, reducing replacement frequency and maintenance costs.

Flexible Integration – Flanged fittings, multiple wattage options, and optional control panels allow easy integration into a variety of industrial systems.

Energy Efficiency – Optimized design maximizes heat transfer to the airflow, reducing wasted energy and operational costs.

Why Choose the Flow Torch 800?

TUTCO Farnam’s Flow Torch 800 is more than an industrial heater—it’s a high-performance solution for modern manufacturing and research applications. Its combination of high-volume airflow, rapid response, precision control, and robust construction makes it ideal for operations where efficiency, reliability, and safety cannot be compromised. Whether you require a standard Flow Torch 800 unit or a custom-configured solution, TUTCO Farnam provides the expertise, engineering support, and quality components needed to optimize your system.

Resources

Control Systems & Temperature Regulation

Check out these upgrade options for the Flow Torch™

Control Panels

Closed-loop heater control systems use a power controller,

temperature controller, and thermocouples to monitor and provide

constant output temperature.

Insulation Blankets

Our insulation blankets are made specifically for the Flow Torch

family of products. Improve safety for people and products, and

save money by reducing waste heat.

Additional Information

Exhaust Fitting

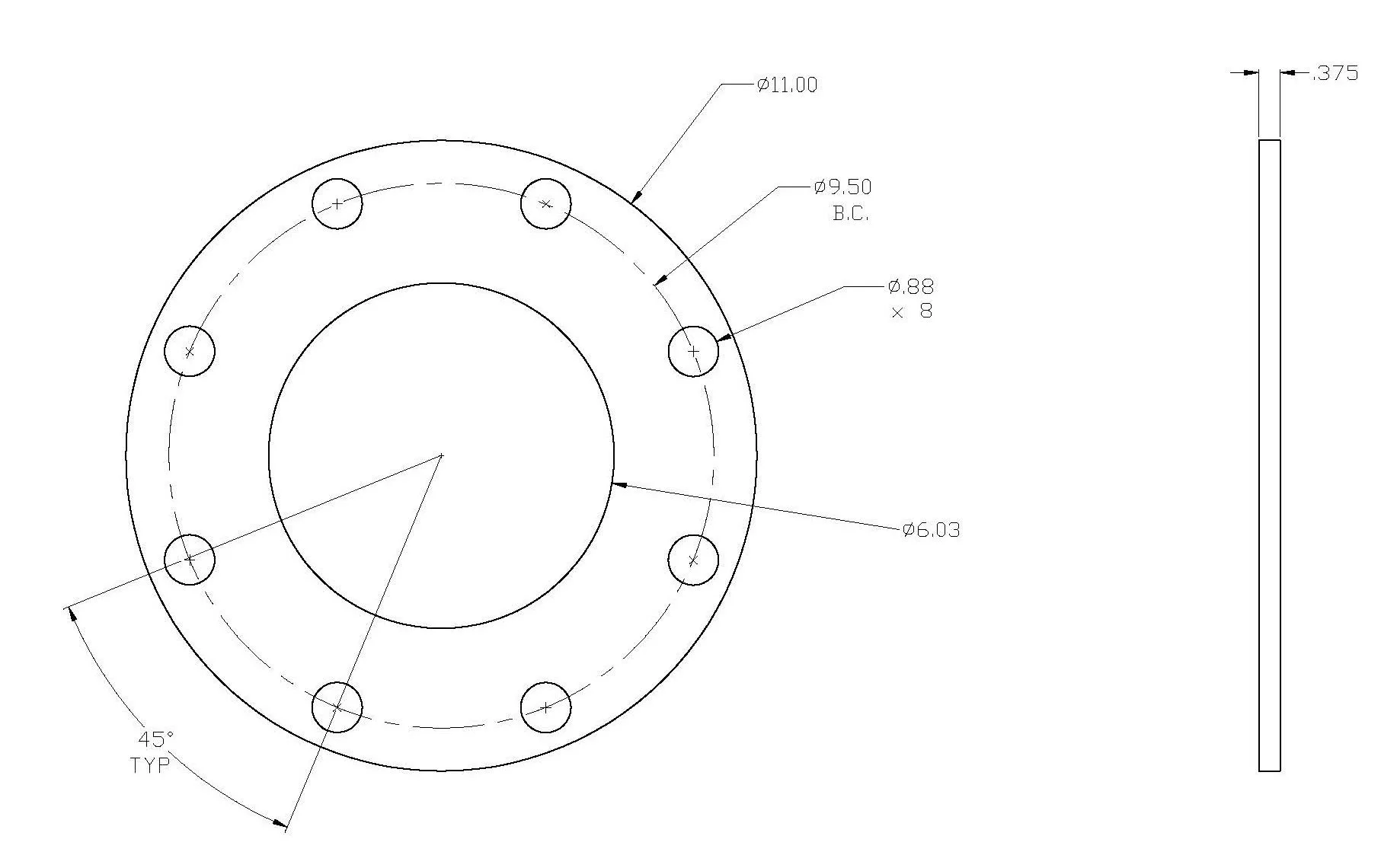

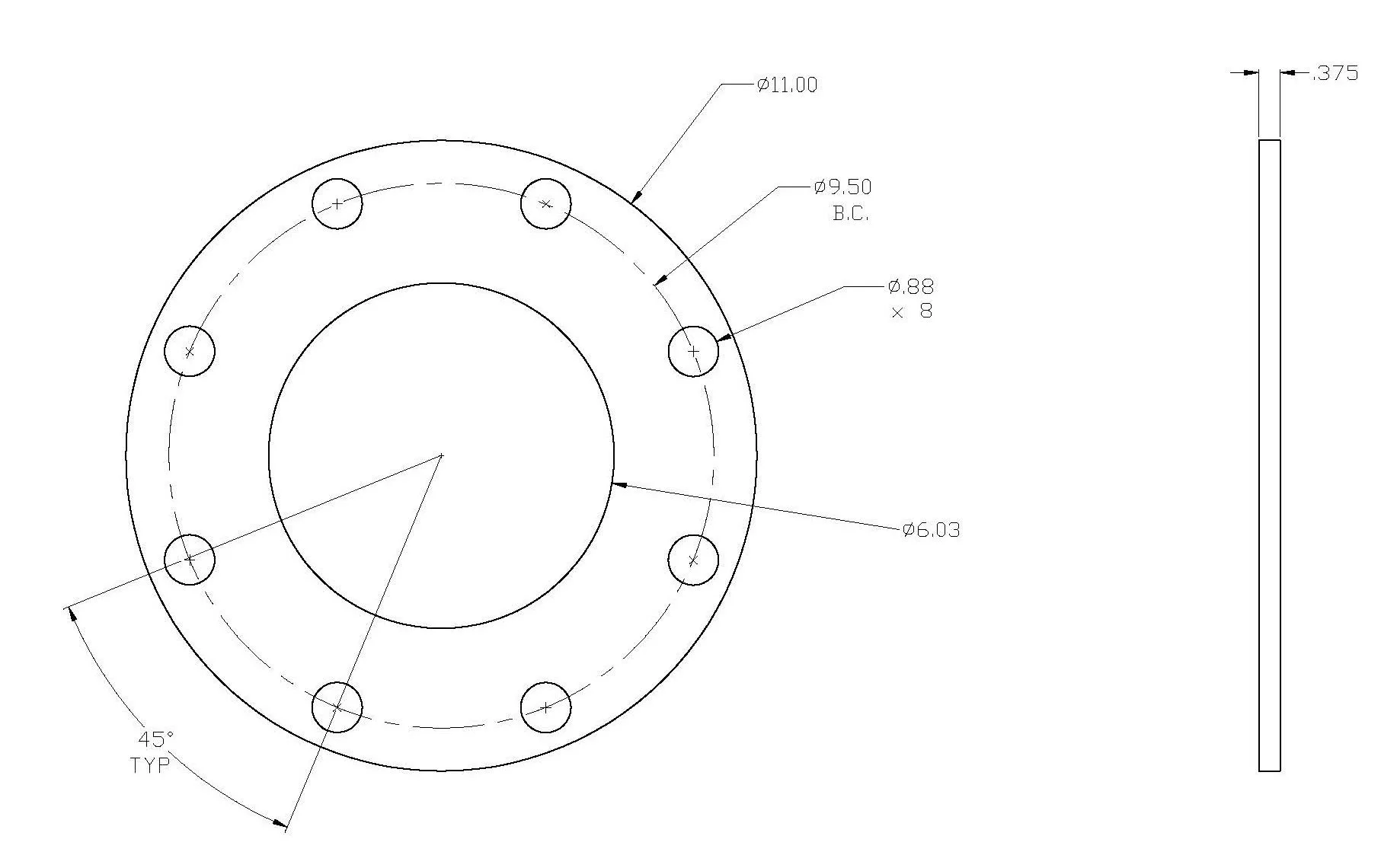

11" Flanged Fitting

Exhaust Fitting

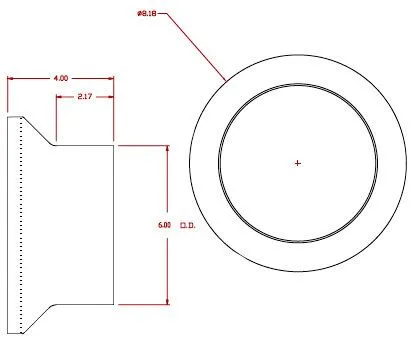

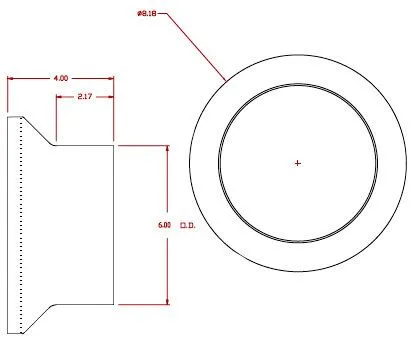

6" Diameter Tube

Exhaust Fitting

4" Diameter Tube

Exhaust Fitting

3" Diameter Tube

Inlet Fitting

11" Flanged Fitting

Inlet Fitting

6" Diameter Tube

Inlet Fitting

4" Diameter Tube

Inlet Fitting

3" Diameter Tube

Frequently Asked Questions

Yes. It is specifically designed for continuous-duty, high-temperature operation in industrial environments. The open-coil design dissipates heat efficiently, while the stainless steel body ensures long-term durability under demanding cycles.

Because the heater is optimized for low pressure drop, it integrates well with blower systems. However, verify that the blower maintains consistent SCFM at operating temperature, as air density decreases when heated. For applications using VFD-controlled blowers, we suggest implementing airflow verification interlocks.

Minimum SCFM requirements increase with wattage to prevent overheating of the coil. For example, 20 kW requires 76 SCFM, while 75 kW requires 286 SCFM. When in doubt, oversizing airflow is safer than undersizing. If airflow drops below the minimum threshold, the heater’s temperature will spike rapidly.

The Flow Torch 800 is engineered for extreme airflow volumes up to 2,000 SCFM, making it the highest-capacity open-coil heater in the product line. Its 8-inch diameter body and wattage options up to 75 kW allow it to serve applications far beyond the thermal and airflow capabilities of smaller models.