Flow Torch™ 400

The Flow Torch™ 400 is an open coil air heater designed for high flow rates at low pressure drop due to its efficient design with minimal flow restrictions. The robust construction of this 4” diameter stainless steel heater offers reliable long-life performance and reduced operational cost. The Flow Torch™ 400 incorporates a spiral wound element of the highest grade material, providing quick heat up and cool down cycles with maximum heat transfer.

The Flow Torch™ 400 is capable of operating with airflow of 500 SCFM and a maximum operating pressure of 3 PSIG*. Maximum output temperature is 482°C (900°F). All Flow Torch Heaters are UL recognized components under UL file number E365755. Regenerative Blowers available with complete systems.

* Note: minor leakage through stranded leads

Flanged Fittings!

We have flanges available as a standard option on our Flow Torch heaters. Click here to build your FT400, FT600 & FT800 with flanged inlet and exhaust fittings.

Wattage and Voltage Options

Short Version:

208V, single phase, 2.0kW-19.0kW

208V, three phase, 2.0kW-19.0kW

240V, single phase, 2.0kW-19.0kW

240V, three phase, 2.0kW-19.0kW

380V, three phase 2.0kW-19.0kW

480V, three phase, 3.0kW-19.0kW

575V, three phase, 3.0kW-19.0kW

Long Version:

208V, single phase, 20.0kW-24.0kW

208V, three phase, 20.0kW-24.0kW

240V, single phase, 20.0kW-30.0kW

240V, three phase, 20.0kW-30.0kW

380V, three phase 20.0kW-33.0kW

480V, three phase, 20.0kW-35.0kW

575V, three phase, 20.0kW-35.0kW

Fitting Options

Inlet Fitting:

2F - 2" FNPT

3T - 3" O.D. Tube

NF - No Fitting (4" O.D.)

Exhaust Fitting:

2F - 2" FNPT

3T - 3" O.D. Tube

NF - No Fitting (4" O.D.)

| MAX WATT | MAX INLET | MAX EXHAUST | MIN SCFM | MAX SCFM | PSIG* |

| 35000 W | 250º F | 900º F | 19 | 500 | 3 |

* with minimal leakage.

| WATTAGE | 5.0 kW | 10.0 kW | 15.0 kW | 20.0 kW | 25.0 kW | 30.0 kW | 35.0 kW |

| MIN. SCFM REQUIRED | 19.1 | 38.2 | 57.2 | 76.3 | 95.4 | 114.5 | 133.6 |

Standard power of 2 kW to 35 kW is available for a wide range of applications

Specifications

Mounting.................................................Horizontal / Vertical

Heater Body.....................................................Stainless Steel

Inlet Fitting......................................................Stainless Steel

Exhaust Fitting................................................Stainless Steel

Control Panels are also available to provide precise temperature regulation.

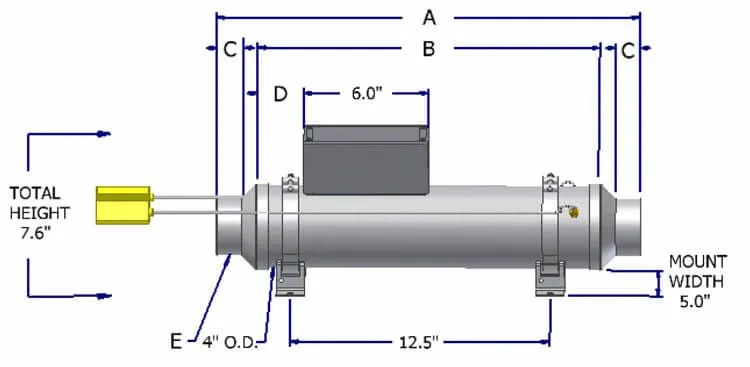

| A | INLET FITTING | B | EXHAUST FITTING | C | |

| FT400 Short | 16.5" | NF | 0 | NF | 0 |

| FT400 Short | 16.5" | 2F | 2.02" | 2F | 2.02" |

| FT400 Short | 16.5" | 3T | 3.0" | 3T | 3.0" |

| FT400 Long | 22.0" | NF | 0 | NF | 0 |

| FT400 Long | 22.0" | 2F | 2.02" | 2F | 2.02" |

| FT400 Long | 22.0" | 3T | 3.0" | 3T | 3.0" |

Applications

- Hot Air Curtains

- Air Drying

- Baking

- Chemical Processing

- Dehumidification

- Laminating

- Textile Applications

- Web Drying Ink Drying

- Paint Baking/Drying

- Plastic Curing

- Metallization Exhaust

- Gas Heating Hopper

- Drying Sterilization

Resources

Additional Information

Exhaust Fitting

9" Flanged Fitting

Exhaust Fitting

2" NPT Female

Exhaust Fitting

3" Diameter Tube

Inlet Fitting

2" NPT Female

Inlet Fitting

3" Diameter Tube

Inlet Fitting

9" Flanged Fitting

Complete your Thermal System

Check out these upgrade options for the Flow Torch™

Control Panels

Closed-loop heater control systems use a power controller,

temperature controller, and thermocouples to monitor and provide

constant output temperature.

Insulation Blankets

Our insulation blankets are made specifically for the Flow Torch

family of products. Improve safety for people and products, and

save money by reducing waste heat.

Frequently Asked Questions

For optimal coil longevity and temperature uniformity, maintain at least 6–12 inches of unobstructed airflow upstream and downstream. Reducers, elbows, dampers, or instrumentation placed too close to the coil can cause airflow distortion and temperature hot spots.

Open-coil heaters do not introduce particulates, but they require filtered air to avoid debris accumulation on the element. With proper filtration, they are well-suited for environments such as electronics assembly, medical device processing, and laboratory R&D.

Yes, but minimum SCFM must always be maintained to prevent element over-temperature. If your system experiences variable flow, you should incorporate a low-flow interlock, airflow sensor, or differential pressure switch to ensure safe operation during dips or spikes in airflow.

Choose the short version when space is limited or when wattage requirements are below 19 kW. Select the long version if you need wattages up to 35 kW or want improved temperature uniformity across a longer heat zone. The additional length also helps reduce coil loading per inch, extending heater life.