Medical

TUTCO Farnam has designed hundreds of heaters for surgical, laboratory, and patient comfort applications around the world. Over 70% of patient warming blankets in use today employ a custom TUTCO Farnam heating element.

The medical device industry demands the highest standards, with OEMs and component manufacturers required to meet complex and stringent specifications. At TUTCO Farnam, we have extensive experience navigating the rigorous requirements of Class III medical device development. Our engineers work closely with medical OEMs to develop custom heating solutions that meet and exceed the toughest tolerances. We stand by our clients every step of the way as component precision is measured and tested.

Over 70% of patient warming blankets in use today employ a custom TUTCO Farnam heating element.

Not all custom heater manufacturers are willing or able to meet the rigorous requirements demanded by the Medtech industry. Tolerances are tight and development cycles are typically longer and more involved. These are working relationships that can span weeks or years. Medical OEMs demand exceptional components that must perform consistently and reliably use after use. At TUTCO Farnam, we are highly capable of creating solutions that stand up to the strict standards of the medical device industry.

Surgical

Temperature regulation pervades the surgical environment. OEM equipment employed in surgical applications must perform reliably and with precision. IV drip warmers and surgical warming blankets provide safe thermal conditions. Heaters used for sterilization as well as dehumidification reduce operating room pathogens. Patient outcomes are drastically improved when fluids are thermally controlled and environmental conditions are sterile. Applications include specialty instruments, sterilization, medical storage devices, IV drip warmers, ultrasonic cleaners, fast fluid warmers, and syringe heaters.

Specialty Instruments

Whether it's a critical medical device requiring precise thermal management or a specialized industrial system, our engineering team works closely with clients to develop heating solutions that meet exact performance, size, and safety specifications. Each heating element is designed on a per-case basis, ensuring optimal efficiency, reliability, and integration within the overall system.

Sterilization

Custom-shaped heaters ensure seamless integration into complex system designs, optimizing space and performance. High-temperature capabilities allow for effective sterilization by reaching and maintaining the necessary heat levels to eliminate harmful pathogens. Rapid ramp-up times further enhance efficiency by reducing cycle durations, ensuring quicker turnaround times for sterilized instruments and equipment.

Medical Storage Device

TUTCO Farnam engineered a specialized heating element that seamlessly integrated fan mounting brackets into the heating element housing, creating a cost-effective and space-saving solution. This innovative design reduced the number of components required, simplifying assembly and lowering manufacturing costs. Additionally, the heater was designed for easy retrofitting into existing equipment, eliminating the need for extensive modifications.

IV Drip Warmer

IV drop warmers play a critical role in patient care by ensuring that fluids are delivered at body temperature, preventing the discomfort and potential complications associated with cold infusions. Prewarmed fluids help maintain normothermia, reducing the risk of hypothermia in surgical and trauma patients while promoting better circulation and overall comfort.

Patient Comfort

Medical Device OEMs rely on TUTCO Farnam for their heating element needs. Fluid, fabric, medications, and therapeutic materials are warmed by TUTCO Farnam heaters in medical facilities around the globe. From CPAPs to warming cabinets, medical devices require custom specialty heaters designed to improve patient comfort as well as medical outcomes. Applications include hydrotherapy, ventilators, vapor therapy machines, hyperthermia fluid therapy, saline temperature control, fluid warming, warming pads, nebulizers, dialysis, and CPAP machines.

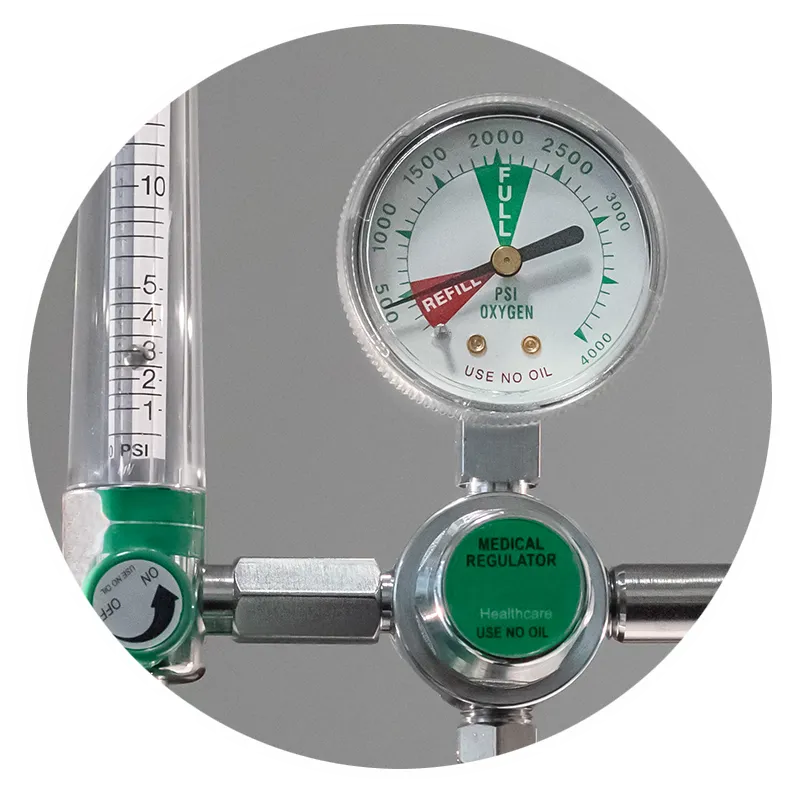

Oxygen and Ventilation Warming

Oxygen and ventilation systems rely on precise thermal control to ensure that decompressed air, which is naturally cold, is delivered at a safe and comfortable temperature. Without proper warming, cold air can cause discomfort, airway irritation, and even adverse physiological effects in patients. TUTCO Farnam designs advanced heating elements that integrate seamlessly into oxygen and ventilation equipment, providing consistent and efficient thermal regulation.

Patient Warming Systems

TUTCO Farnam engineered a highly compact heating solution for patient warming systems used in operating rooms worldwide. The design featured a staged ramp-up heating process, ensuring precise temperature control while preventing sudden thermal spikes. Safety was a top priority, so the heater incorporated multiple safeguards, including over-temperature protection and fail-safe mechanisms, to meet stringent medical standards.

Warming Cabinets

Warming cabinets serve a vital role in both medical and food service industries by maintaining precise temperatures for comfort and quality. In healthcare settings, they ensure that towels, blankets, pads, and fluids are prewarmed, providing soothing warmth for patients and reducing the risk of hypothermia. In food service, they help keep meals at optimal temperatures for safe holding and transport.

Humidity Control

Precise humidity control is essential in medical settings for patient comfort, effective medicinal delivery, and infection control. Maintaining optimal moisture levels in the air reduces the spread of airborne pathogens, enhancing infection control in hospitals and clinics. TUTCO Farnam provides advanced heating solutions that support reliable humidity regulation, ensuring safer and more comfortable medical environments.

Imaging and Diagnostics

Medical equipment manufacturers gain a competitive advantage when thermal control is properly addressed. Doctors and technicians want higher quality results from patient imaging and analytical test data. Greater resolution means better information on which to base critical medical decisions. Thermal control is a major factor in increasing quality, resolution, and speed.

CT Scanner

Image quality was greatly improved by heating the internal temperatures of the apparatus. This turnkey solution including elements, blower, sensor, and controller offering even and regulated temperature inside the donut shape of a CT scanner.

Blood Analyzer

A newly designed Blood Analyzing Instrument required a very specialized miniature air heater and very precise performance. No Instrument had ever performed a process like this and there had never been a heater like this.