Heat Torch™ 075 Inline Air Heater

High-Capacity, Focused Heating for Moderate to High Airflow Applications

The Heat Torch™ 075 from TUTCO Farnam is a 0.75" (19 mm) diameter inline air heater designed to deliver moderate to high airflow with precise, focused heating. With over twice the airflow capacity of the Heat Torch™ 050, the 075 is ideal for applications requiring higher air volumes while maintaining concentrated heat for accurate, repeatable thermal processes.

Available in ceramic and mica core configurations, the 075 can reach maximum output temperatures of 1300°F (704°C) for ceramic cores or 932°F (500°C) for mica cores, supporting a wide variety of laboratory, industrial, and manufacturing applications. It operates efficiently over an airflow range of 1.3 to 25 SCFM, making it suitable for benchtop testing, assembly line processes, and OEM integration.

The Heat Torch 075’s stainless-steel body, UL-listed components, and flexible horizontal/vertical mounting options provide durability, reliability, and easy system integration. Power options range from 100 W to 1,000 W in 100 W increments, allowing precise matching to system requirements.

| CORE | MAX WATT | MAX INLET | MAX EXHAUST | MIN SCFM | MAX SCFM | PSIG* |

| CERAMIC | 1000 W | 250º F | 1300º F | 1.3 | 25 | 120 |

| MICA | 1000 W | 250º F | 932º F | 1.3 | 25 | 120 |

Key Features & Benefits

Dual-Core Flexibility

Select a ceramic core for high-temperature, heavy-duty applications or a mica core for moderate-temperature processes and faster thermal cycling.

High Airflow Capacity

Handles 1.3–25 SCFM, supporting higher-volume processes than the 050 while maintaining precise heat focus.

Compact and Robust Construction

0.75" stainless-steel body fits easily into constrained setups while providing long-lasting performance.

Rapid Thermal Response

Quick heat-up and cool-down cycles enable responsive temperature adjustments and improved process control.

Versatile Mounting Options

Supports both horizontal and vertical installation to accommodate system design and optimize heat transfer.

UL-Listed Components

Ensures safe, reliable operation in industrial, laboratory, and OEM applications.

Optional Accessories

Thermocouples, thermocouple fittings, and flexible conduit options enhance temperature monitoring, control, and integration with custom systems.

Wattage and Voltage Options

Mica Core (Max. Exhaust of 900ºF)

120V, single phase, 0.2kW-0.9kW

208V, single phase, 0.2kW-0.95kW

240V, single phase, 0.2kW-1.0kW

Ceramic Core (Max. Exhaust of 1300)F)

120V, single phase, 0.2kW-0.9kW

208V, single phase, 0.2kW-1.0kW

240V, single phase, 0.2kW-1.0kW

Specifications

Mounting..........................................Horizontal / Vertical

Leads................................................20 AWG, 12" Long

Heater Body.....................................Stainless Steel

Air Entryway Fitting.........................Stainless Steel

Inlet Fitting......................................1/8" FNPT, 3/8" FNPT, Counterbore 1/2" O.D.

Exhaust Fitting...............................1/4" FNPT, 3/8" FNPT, NF –

No Fitting, TE Reducing Adaptor

Ready to Build Your Solution?

Request a Quote or Contact our Applications Engineers to learn how a Heat Torch™ heater can improve your process consistency, energy efficiency, and thermal performance.

Applications

The Heat Torch™ 075 is designed for high-precision heating at moderate to high airflows, making it ideal for industrial, laboratory, and OEM applications where consistent, focused heat is required over larger volumes. Typical applications include:

Staking and Heat Forming – Apply controlled heat to medium or large thermoplastic components for assembly, forming, or prototyping.

Curing Coatings and Adhesives – Achieve uniform curing of adhesives, coatings, and films, improving bond strength and production quality.

Adhesive Activation – Activate pressure-sensitive or heat-activated adhesives with precision airflow for consistent results.

Drying Processes – Efficiently dry materials, parts, or coatings with controlled airflow across moderate-to-large surfaces.

Heat Shrinking – Precisely shrink tubing or films over larger components or assemblies without affecting nearby areas.

Sterilization – Generate high-temperature airflow to sterilize instruments, packaging, or components in laboratory or industrial settings.

Laboratory Research & Testing – Deliver repeatable, high-volume thermal input for prototype testing, R&D, or material studies.

OEM and Production Line Integration – Perfect for assembly stations, automated manufacturing systems, or modular setups requiring consistent heat over larger airflow volumes.

Electronics and Component Rework – Use for de-soldering, reflow, or thermal processing on small to medium electronic assemblies.

Preheating & Material Conditioning – Condition components prior to bonding, forming, or processing to ensure uniform temperature and minimize thermal stress.

The Heat Torch 075’s high airflow, dual-core options, and focused heat make it a versatile solution for precise heating in moderate- to high-volume applications, delivering consistent, energy-efficient, and repeatable results.

Advantages Over Conventional Heaters

The Heat Torch™ 075 provides several key advantages that set it apart from traditional small air heaters and hot air tools:

Dual-Core Flexibility – Choose ceramic for high-temperature, heavy-duty processes or mica for moderate-temperature, fast-cycling applications.

High Airflow Capacity – Handles 1.3–25 SCFM, supporting higher-volume applications beyond the 050 while maintaining focused heat.

Concentrated, Efficient Heating – Minimized heat loss ensures nearly all energy is delivered to the target area, improving efficiency and process quality.

Rapid Thermal Response – Quick heat-up and cool-down cycles enable precise temperature control and process adjustments.

Durable, Compact Design – Stainless-steel construction withstands thermal cycling, and compact form factor fits in constrained spaces or modular systems.

Versatile Mounting & Fitting Options – Horizontal/vertical installation and multiple inlet/exhaust configurations allow easy integration into custom systems.

UL-Listed for Safety & Compliance – Components meet UL standards for reliable operation in industrial, laboratory, and OEM applications.

Optional Process Monitoring – Thermocouples, fittings, and flexible conduit enable advanced temperature measurement and control.

Minimal Maintenance – Rugged design reduces wear, downtime, and replacement costs compared to traditional air heaters.

Supported by TUTCO Farnam Expertise – Decades of engineering experience provide application guidance, integration support, and process optimization.

Why Choose TUTCO Farnam Heat Torch™ 075 Heaters?

The Heat Torch™ 075 is a high-capacity, focused inline heater that balances precise thermal control with higher airflow capabilities. With dual-core options, broad voltage and wattage ranges, and optional accessories, it is ideal for laboratory, industrial, or OEM applications requiring accurate, repeatable heating over larger airflow volumes.

Resources

Additional Information

| AIRFLOW (SCFM) | PRESSURE DROP (PSIG) |

| 1.3 | 0.1 |

| 2 | 0.2 |

| 3 | 0.5 |

| 4 | 0.8 |

| 6 | 1.8 |

| 8 | 3.2 |

| 10 | 5.0 |

| 15 | 11.3 |

| 20 | 20.0 |

| 25 | 31.3 |

| WATTAGE | MINIMUM FLOW REQUIRED AT MAX POWER INLET AIR TEMPERATURE 72º F (SCFM) |

| 100 | 1.3 |

| 200 | 1.3 |

| 300 | 1.3 |

| 400 | 1.3 |

| 500 | 1.3 |

| 600 | 1.3 |

| 700 | 1.3 |

| 800 | 1.4 |

| 900 | 1.7 |

| 1000 | 1.8 |

Exhaust Fitting

3/8" NPT Female

Exhaust Fitting

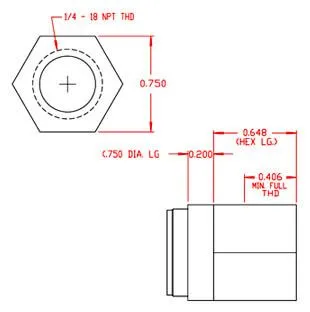

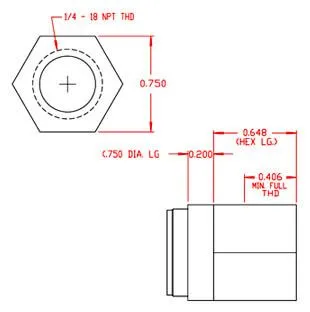

1/4" NPT Female

Exhaust Fitting

No Fitting

Exhaust Fitting

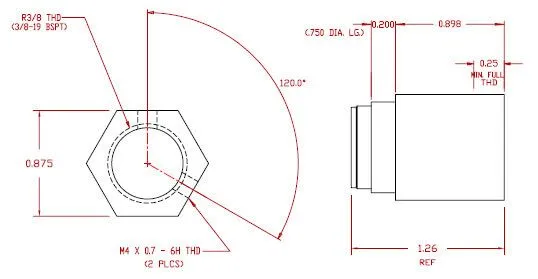

R3/8=3/8-19 BSPT Female

Exhaust Fitting

3/4" to 1/2" Reducing Adaptor

Exhaust Fitting

3/8" NPT Female

Exhaust Fitting

3/8" NPT Female

Exhaust Fitting

1/4" NPT Female

Exhaust Fitting

3/8" NPT Female

Exhaust Fitting

3/4" to 1/2" Reducing Adaptor

Exhaust Fitting

3/8" NPT Female

Exhaust Fitting

R3/8=3/8-19 BSPT Female

Exhaust Fitting

3/8" NPT Female

Inlet Fitting

Counterbore 1/2" Female

Inlet Fitting

1/8" NPT Female

Inlet Fitting

R1/4=1/4-19 BSPT Female

Frequently Asked Questions

Yes. It is rated for up to 120 PSIG with minimal leakage, making it compatible with compressed air or non-combustible gas systems.

Yes. Accessories such as thermocouples, thermocouple fittings, flexible conduit assemblies, and custom adaptors are available to enhance temperature monitoring, safety, and system integration.

Choose ceramic for high-temperature, heavy-duty, or continuous-use applications needing maximum heat.

Choose mica for moderate temperatures, faster thermal cycling, or applications requiring frequent on/off operation.

The Heat Torch 075 supports significantly higher airflow (1.3–25 SCFM) while maintaining precise, focused heat. It is ideal for applications requiring greater air volume without sacrificing thermal accuracy.