Flow Torch™ 600

Efficient High-Flow Air Heating for Industrial and Laboratory Applications

The Flow Torch™ 600 is a high-performance open coil air heater from TUTCO Farnam, engineered for applications that demand high airflow at low pressure drop. With its innovative low-mass coil design, the Flow Torch 600 maximizes heat transfer while minimizing flow restrictions, ensuring efficient, consistent heating for industrial processes.

Constructed with a 6-inch diameter stainless steel body, this heater offers long-lasting durability and reduced operational costs. At the heart of the Flow Torch 600 is a spiral wound open coil element made from premium materials, delivering rapid heat-up and cool-down cycles to optimize thermal efficiency. Designed to provide reliable performance in demanding environments, the Flow Torch 600 is ideal for manufacturing, R&D, chemical processing, and other industrial applications where precision and efficiency are critical.

Flanged Fittings! We have flanges available as a standard option on our Flow Torch heaters. Click here to build your FT400, FT600 & FT800 with flanged inlet and exhaust fittings.

| MAX WATT | MAX INLET | MAX EXHAUST | MIN SCFM | MAX SCFM | PSIG* |

| 60000 W | 392º F | 932º F | 38 | 1100 | 3 |

* with minimal leakage.

| WATTAGE | 10 kW | 15 kW | 20 kW | 25 kW | 30 kW | 35 kW | 40 kW | 45 kW | 50 kW | 55 kW | 60 kW |

| MIN. SCFM REQUIRED | 38.2 | 57.2 | 76.3 | 95.4 | 114.5 | 133.6 | 152.6 | 171.7 | 190.8 | 209.9 | 229.0 |

Key Features & Benefits

High Airflow Capacity with Low Pressure Drop

Capable of handling up to 1,100 SCFM at a maximum operating pressure of 3 PSIG, the Flow Torch 600 ensures large-volume airflow without excessive resistance. This minimizes energy consumption and improves system efficiency.

Rapid Heat-Up and Cool-Down

The open coil design allows the heater to reach operating temperatures quickly and cool down just as efficiently. This fast thermal response enhances process control, reduces downtime, and improves productivity.

Wide Temperature Range

The Flow Torch 600 reaches a maximum output temperature of 482°C (900°F), with standard inlet temperatures up to 392°F and customization options for higher inlet temperatures. This makes it versatile for a variety of industrial and laboratory applications.

Durable Construction

The stainless steel heater body, inlet, and exhaust fittings are designed for long-term performance in harsh industrial conditions, reducing maintenance requirements and operational interruptions.

Flexible Power Options

Available in wattages from 7 kW to 60 kW, the Flow Torch 600 can be tailored to meet the specific thermal requirements of your system.

UL Recognized Components

All Flow Torch heaters are UL recognized under UL file number E365755, ensuring safety, reliability, and compliance with industrial standards. Flanged Fittings Standard flanged inlet and exhaust fittings make integration into your air handling system straightforward. Flanged options are available for the FT400, FT600, and FT800 models to meet your system configuration needs.

Optional Control Panels

Control panels provide precise temperature regulation, allowing operators to maintain consistent process conditions and optimize thermal performance.

Specifications

Mounting....................................................Horizontal / Vertical

Heater Body...............................................Stainless Steel

Inlet Fitting................................................Stainless Steel

Exhaust Fitting...........................................Stainless Steel

*Note: Minor leakage may occur through stranded leads.

Ready to Build Your Solution?

Request a Quote or Contact our Applications Engineers to learn how a Flow Torch™ heater can improve your process consistency, energy efficiency, and thermal performance.

Applications

The Flow Torch 600 is engineered to provide reliable, high-volume, controlled air heating for a wide range of industrial processes:

Hot Air Curtains – Maintain separation between temperature zones in industrial spaces, reducing energy loss.

Air Drying – Efficiently dry coatings, adhesives, textiles, or other materials while maintaining precise control over air temperature.

Baking – Ideal for ovens and industrial baking processes requiring consistent airflow and temperature distribution.

Chemical Processing – Support drying, heating, or curing processes in chemical manufacturing with precision airflow and thermal control.

Dehumidification – Enable controlled drying in humidity-sensitive environments for products or materials.

Laminating & Coating – Provide uniform heated airflow to achieve consistent adhesion, curing, or coating thickness.

Textile Applications – Maintain precise airflow and temperature for fabric drying, finishing, or treatment.

Web & Ink Drying – High-volume airflow allows efficient drying for printing presses, coated webs, and continuous processing equipment.

Paint Baking / Drying – Rapidly cure paint or coatings to reduce cycle times and improve process efficiency.

Plastic Curing & Metallization Exhaust – Stable high-temperature airflow supports plastics processing or metallization applications.

Gas Heating & Hopper Drying – Deliver controlled heated airflow for drying, material handling, or gas conditioning processes.

Sterilization – Provide heated airflow for sterilizing equipment or products in industrial and laboratory settings.

Flow Torch 600 heaters deliver fast, efficient, and precise air heating, making them ideal for applications that require both high performance and process reliability.

Advantages Over Conventional Heaters

The Flow Torch 600 stands out for delivering industrial-grade performance with exceptional efficiency:

High Airflow, Low Resistance – Designed to maximize air movement while minimizing pressure drop, reducing energy consumption and improving system efficiency.

Rapid Thermal Response – Open coil construction allows near-instantaneous heating and fast cool-down, ensuring precise temperature control.

Durable & Reliable – Stainless steel body and premium coil materials ensure long-lasting performance and minimal maintenance.

Flexible Integration – Flanged fittings, wattage options, and control panel compatibility allow seamless installation into a variety of industrial systems.

Energy Efficient – Optimized heat transfer reduces wasted energy, lowering operational costs while maintaining high-performance output.

Why Choose the Flow Torch 600?

The Flow Torch 600 is more than an industrial air heater—it’s a high-capacity, reliable solution for demanding industrial and laboratory applications. With high airflow, rapid thermal response, customizable options, and robust construction, the Flow Torch 600 ensures your process operates efficiently, consistently, and safely. Whether you require a standard Flow Torch 600 unit or a customized configuration, TUTCO Farnam provides the expertise, engineering support, and quality components to deliver a heater that meets your exact requirements.

Resources

Control Systems & Temperature Regulation

Check out these upgrade options for the Flow Torch™

Control Panels

Closed-loop heater control systems use a power controller,

temperature controller, and thermocouples to monitor and provide

constant output temperature.

Insulation Blankets

Our insulation blankets are made specifically for the Flow Torch

family of products. Improve safety for people and products, and

save money by reducing waste heat.

Additional Information

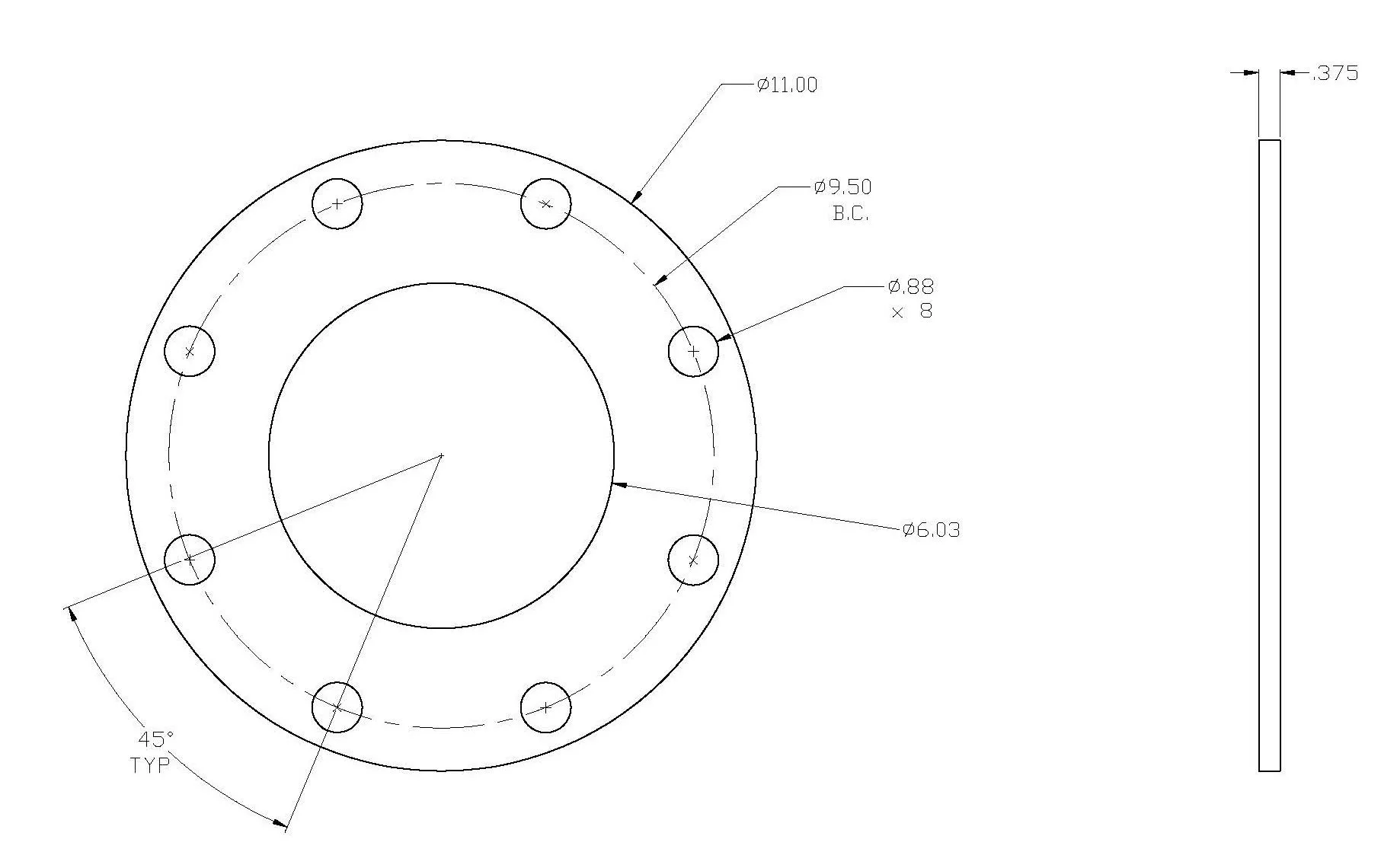

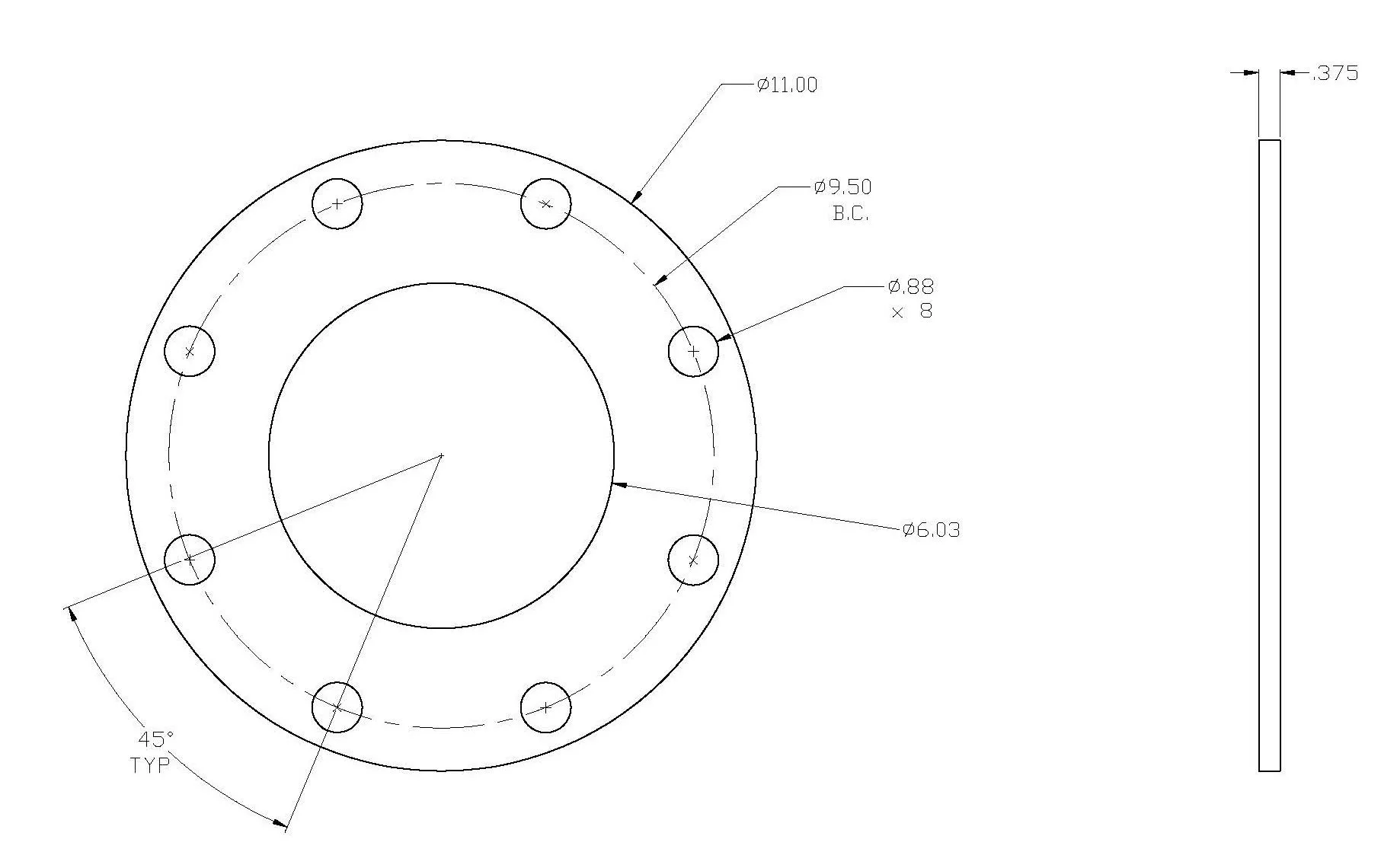

Exhaust Fitting

11" Flanged Fitting

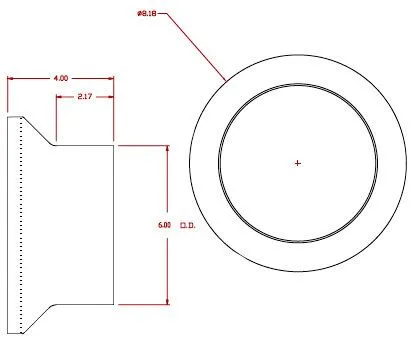

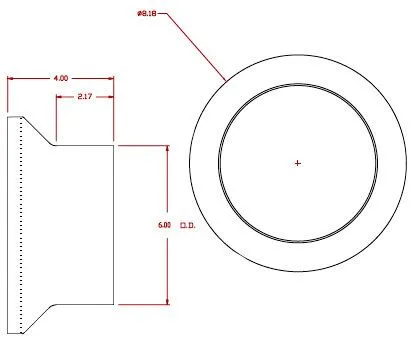

Exhaust Fitting

6" Diameter Tube

Exhaust Fitting

4" Diameter Tube

Exhaust Fitting

3" Diameter Tube

Inlet Fitting

11" Flanged Fitting

Inlet Fitting

6" Diameter Tube

Inlet Fitting

4" Diameter Tube

Inlet Fitting

3" Diameter Tube

Frequently Asked Questions

Yes, but recirculating systems must carefully manage inlet temperature. Since the Flow Torch 600 has a maximum inlet temperature of 392°F (200°C), systems designed for recirculation need temperature monitoring to prevent unintended preheat accumulation. Many customers add a secondary high-limit sensor upstream to protect the heater.

Yes. The heater is specifically engineered for high-flow, low-pressure systems and is fully compatible with regenerative blowers, plant air movers, and other high-volume airflow sources.

This model excels in high-volume industrial processes, including hot air curtains, web and ink drying, chemical processing, textile drying, dehumidification, paint baking, plastics curing, gas heating, hopper drying, and sterilization. Any operation requiring large airflow combined with fast thermal response will benefit from the 600.

The Flow Torch 600 is designed for extremely high airflow applications, supporting up to 1,100 SCFM with minimal pressure drop. Its 6-inch diameter body, open-coil design, and wattage options up to 60 kW make it the highest-capacity heater in the Flow Torch lineup.