Flow Torch™ 400

Compact, High-Flow Air Heating for Industrial and Laboratory Applications

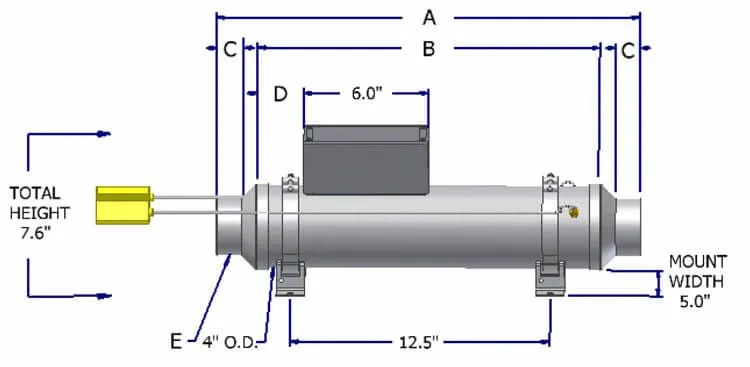

The Flow Torch™ 400 from TUTCO Farnam is a high-performance open coil air heater designed to deliver efficient airflow at low pressure drop. With its low-mass spiral wound coil and streamlined construction, the Flow Torch 400 maximizes heat transfer while minimizing flow restrictions, making it ideal for smaller-scale industrial processes, research applications, and specialized air-handling systems.

Constructed with a 4-inch diameter stainless steel body, the Flow Torch 400 is built for durability, long-life performance, and reduced operational cost. Its premium spiral wound element provides rapid heat-up and cool-down cycles, enabling precise temperature control and efficient thermal management. Whether your operation involves manufacturing, R&D, chemical processing, or laboratory testing, the Flow Torch 400 offers reliable performance in a compact, versatile form factor.

| MAX WATT | MAX INLET | MAX EXHAUST | MIN SCFM | MAX SCFM | PSIG* |

| 35000 W | 250º F | 900º F | 19 | 500 | 3 |

* with minimal leakage.

| WATTAGE | 5.0 kW | 10.0 kW | 15.0 kW | 20.0 kW | 25.0 kW | 30.0 kW | 35.0 kW |

| MIN. SCFM REQUIRED | 19.1 | 38.2 | 57.2 | 76.3 | 95.4 | 114.5 | 133.6 |

Key Features & Benefits

High Airflow with Minimal Resistance

Capable of handling up to 500 SCFM at a maximum operating pressure of 3 PSIG, the Flow Torch 400 delivers high-volume airflow efficiently, reducing energy consumption and improving system performance.

Rapid Thermal Response

The open coil design heats quickly and cools just as efficiently, enabling fast thermal cycles and precise process control, which is essential for research, testing, and production applications.

Wide Operating Temperature Range

The Flow Torch 400 achieves a maximum output temperature of 482°C (900°F), with inlet temperatures up to 250°F for standard configurations. Customization options are available for higher inlet temperatures, making the heater suitable for diverse applications.

Robust Construction

Stainless steel heater body, inlet, and exhaust fittings provide long-lasting durability, ensuring the heater performs reliably even in demanding industrial or laboratory environments.

UL Recognized Components

All Flow Torch heaters are UL recognized under UL file number E365755, ensuring safety, reliability, and compliance with industrial standards.

Flanged Fittings

Optional flanged inlet and exhaust fittings simplify integration into existing ductwork or air-handling systems. Available for the FT400, FT600, and FT800 series.

Optional Control Panels

Optional control panels enable precise temperature regulation, maintaining consistent airflow temperatures and improving process stability.

Wattage and Voltage Options

Short Version:

208V, single phase, 2.0kW-19.0kW

208V, three phase, 2.0kW-19.0kW

240V, single phase, 2.0kW-19.0kW

240V, three phase, 2.0kW-19.0kW

380V, three phase 2.0kW-19.0kW

480V, three phase, 3.0kW-19.0kW

575V, three phase, 3.0kW-19.0kW

Long Version:

208V, single phase, 20.0kW-24.0kW

208V, three phase, 20.0kW-24.0kW

240V, single phase, 20.0kW-30.0kW

240V, three phase, 20.0kW-30.0kW

380V, three phase 20.0kW-33.0kW

480V, three phase, 20.0kW-35.0kW

575V, three phase, 20.0kW-35.0kW

Specifications

Mounting....................................................Horizontal / Vertical

Leads..........................................................20 AWG, 12" Long

Heater Body...............................................Stainless Steel

Air Entryway Fitting...................................Stainless Steel

Inlet Fitting................................................Stainless Steel

Exhaust Fitting...........................................Stainless Steel

*Note: Minor leakage may occur through stranded leads.

Ready to Build Your Solution?

Request a Quote or Contact our Applications Engineers to learn how a Flow Torch™ heater can improve your process consistency, energy efficiency, and thermal performance.

Applications

The Flow Torch™ 400 is built for versatility in smaller-scale industrial, laboratory, and manufacturing operations where precise airflow heating is required. Typical applications include:

Hot Air Curtains – Efficiently maintain temperature separation in smaller industrial or laboratory environments.

Air Drying – Rapidly dry coatings, adhesives, textiles, or other materials with precise airflow control.

Baking – Deliver uniform heating for small-scale ovens or curing processes.

Chemical Processing – Provide consistent heat for drying, heating, or curing chemical products.

Dehumidification – Control air temperature in moisture-sensitive processes for consistent drying results.

Laminating & Coating – Achieve precise airflow for adhesives, laminates, or coatings requiring consistent thermal exposure.

Textile Applications – Dry, cure, or finish fabrics with precise air temperature control.

Web & Ink Drying – Support printing and coating operations requiring controlled airflow and heat.

Paint Baking / Drying – Efficiently cure small batches of paint or coatings.

Plastic Curing & Metallization Exhaust – Deliver high-temperature airflow for plastics or metalized surfaces in compact systems.

Gas Heating & Hopper Drying – Provide controlled airflow for small-scale material drying or gas conditioning processes.

Sterilization – Heat airflow for sterilization in laboratory or small-scale industrial applications.

The Flow Torch 400 ensures reliable, precise, and energy-efficient heating across these diverse applications, making it an ideal choice where compact size and performance are critical.

Advantages Over Conventional Heaters

The Flow Torch™ 200 provides several key advantages that set it apart from traditional small air heaters and hot air tools:

High Airflow, Low Resistance – Efficient design delivers consistent airflow without excessive pressure drop, minimizing energy consumption.

Fast Thermal Response – Rapid heat-up and cool-down cycles enable precise temperature control and process efficiency.

Durable Construction – Stainless steel body and high-grade coil materials provide long-lasting reliability.

Flexible Installation – Compact design, multiple fittings, and wattage options make it easy to integrate into a wide variety of systems.

Energy Efficiency – Optimized thermal transfer ensures minimal wasted energy while maintaining high performance.

Minimal Maintenance Requirements – Robust design ensures long service life, reducing downtime and replacement costs.

Supported by TUTCO Farnam Expertise – Backed by decades of air heater innovation and engineering support for system integration, customization, and troubleshooting.

Why Choose TUTCO Farnam Flow Torch™ 400 Heaters?

The Flow Torch 400 is a compact, high-performance solution for industrial, laboratory, and manufacturing applications where precision, efficiency, and reliability are critical. Its open coil design, fast thermal response, customizable power options, and durable construction make it the ideal choice for operators who demand consistent performance in a smaller footprint. Whether you require a standard Flow Torch 400 unit or a customized configuration, TUTCO Farnam delivers the engineering support, quality materials, and technical expertise needed to optimize your process.

Resources

Control Systems & Temperature Regulation

Check out these upgrade options for the Flow Torch™

Control Panels

Closed-loop heater control systems use a power controller,

temperature controller, and thermocouples to monitor and provide

constant output temperature.

Insulation Blankets

Our insulation blankets are made specifically for the Flow Torch

family of products. Improve safety for people and products, and

save money by reducing waste heat.

Additional Information

Exhaust Fitting

9" Flanged Fitting

Exhaust Fitting

2" NPT Female

Exhaust Fitting

3" Diameter Tube

Inlet Fitting

2" NPT Female

Inlet Fitting

3" Diameter Tube

Inlet Fitting

9" Flanged Fitting

Frequently Asked Questions

For optimal coil longevity and temperature uniformity, maintain at least 6–12 inches of unobstructed airflow upstream and downstream. Reducers, elbows, dampers, or instrumentation placed too close to the coil can cause airflow distortion and temperature hot spots.

Open-coil heaters do not introduce particulates, but they require filtered air to avoid debris accumulation on the element. With proper filtration, they are well-suited for environments such as electronics assembly, medical device processing, and laboratory R&D.

Yes, but minimum SCFM must always be maintained to prevent element over-temperature. If your system experiences variable flow, you should incorporate a low-flow interlock, airflow sensor, or differential pressure switch to ensure safe operation during dips or spikes in airflow.

Choose the short version when space is limited or when wattage requirements are below 19 kW. Select the long version if you need wattages up to 35 kW or want improved temperature uniformity across a longer heat zone. The additional length also helps reduce coil loading per inch, extending heater life.