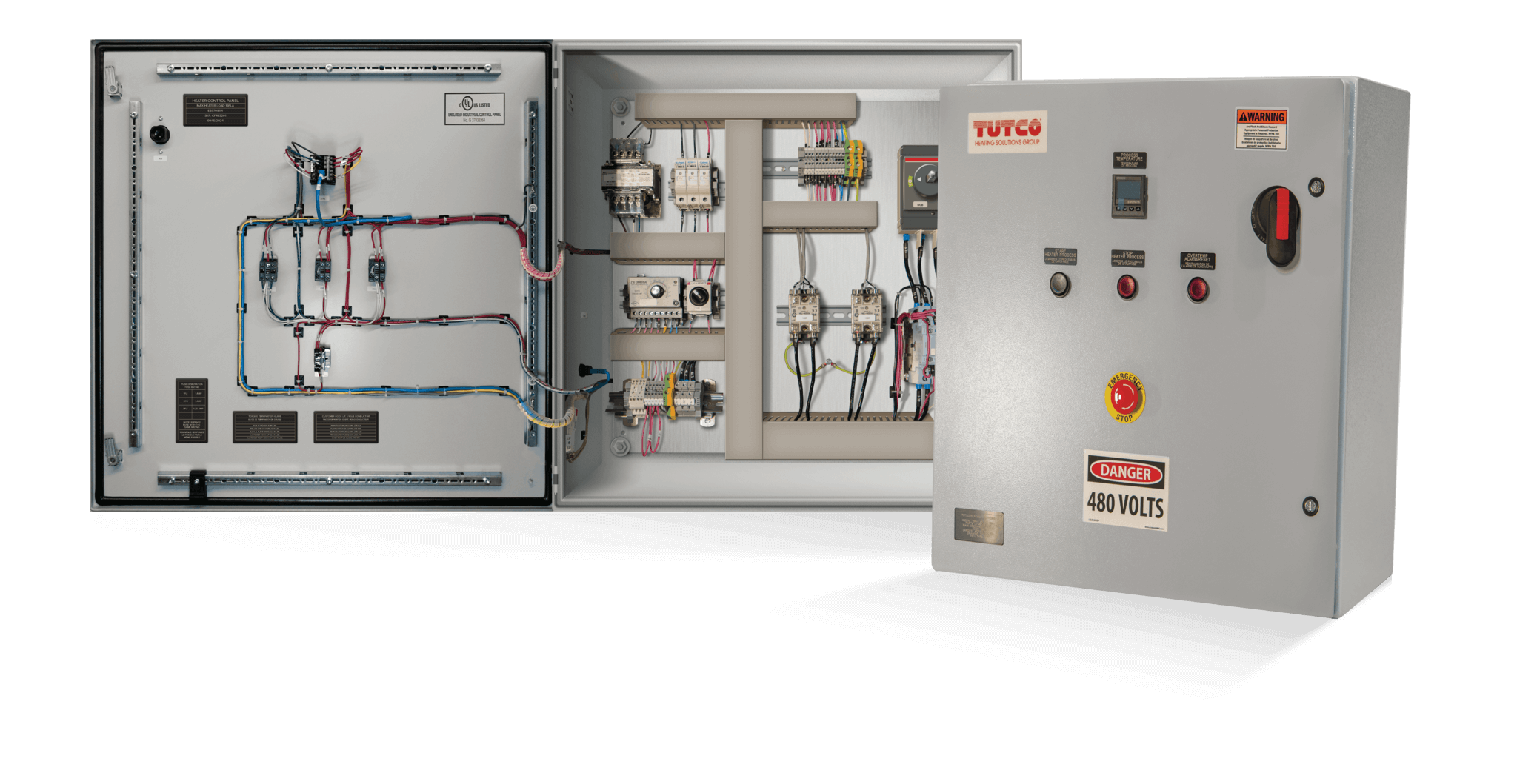

TUTCO Control Panels Offer Environmental Protections

Whether installed on a factory floor, tucked under a canopy in a shipping yard, or fully exposed to summer heat and corrosive air, control panels must maintain integrity while providing dedicated control. At TUTCO Farnam, understanding—and engineering for—environmental exposure is a critical part of the panel design process.

Whether installed on a factory floor, tucked under a canopy in a shipping yard, or fully exposed to summer heat and corrosive air, control panels must maintain integrity while providing dedicated control. At TUTCO Farnam, understanding—and engineering for—environmental exposure is a critical part of the panel design process.

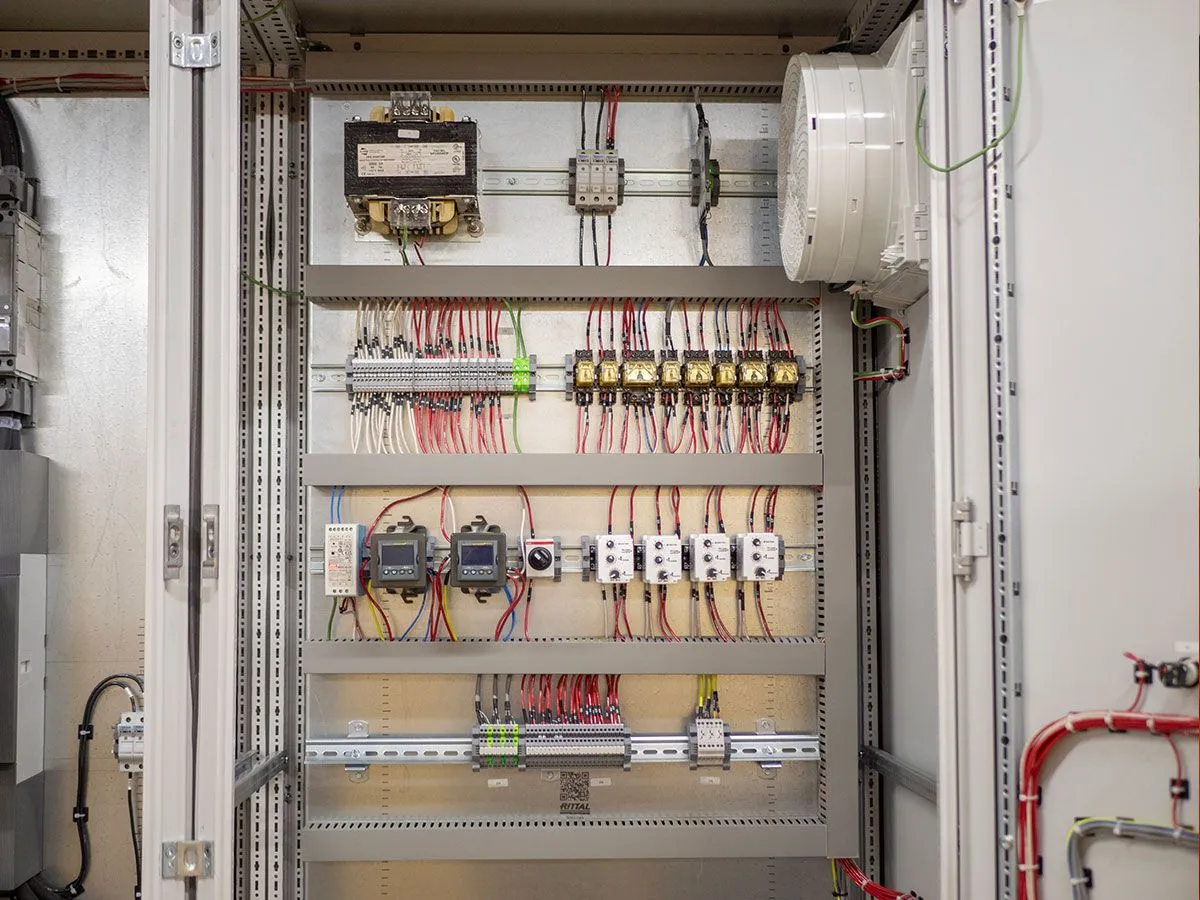

While many in the industry refer to NEMA ratings—such as NEMA 12, 4, or 4X—TUTCO Farnam builds to the UL 508A standard, which aligns closely with NEMA but adds additional third-party oversight and component verification. Every panel component is UL-Type Rated for its specific environmental use, ensuring that what’s installed matches the application.

For customers operating internationally, TUTCO Farnam prefers the IP (Ingress Protection) standard, common in Europe and other regions. Our engineers translate that requirement into an equivalent UL Type Rating classification to ensure the required compliance.

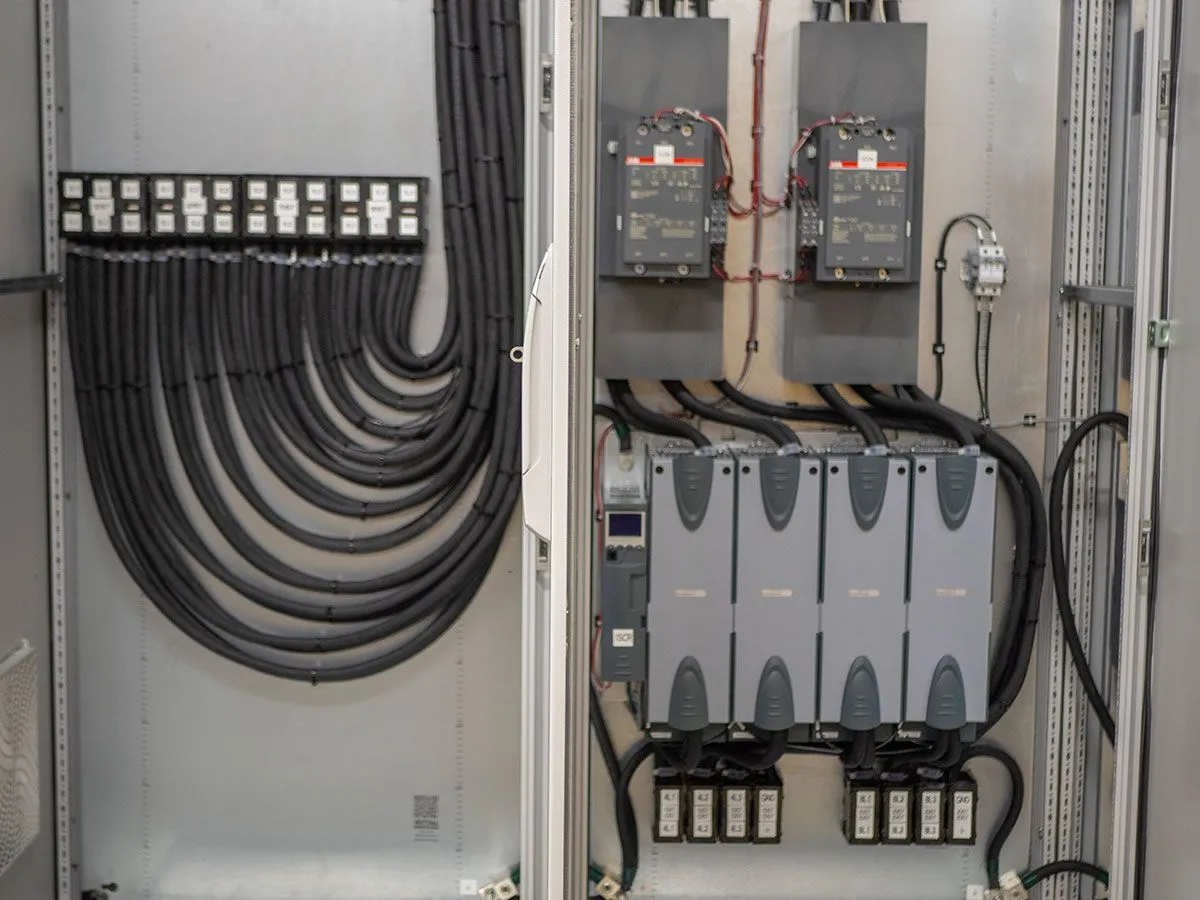

The panel’s environment can dictate its design. Outdoor installations come with additional challenges—sun exposure, precipitation, temperature swings, and even corrosive chemicals or gases. One of the first questions TUTCO Farnam asks: Where is the panel going, and what will it be exposed to?

Solutions for Outdoor and Corrosive Environments Outdoor, open-air locations may require sunshades, drip hoods, or and AC unit. Sheltered environments, like those under a shed or roof, may require less shielding but still demand attention to temperature and humidity. Corrosive will shift the requirement to UL Type 4X, which calls for stainless steel enclosures that can handle corrosion. Hazardous gases which may be explosive may necessitate a completely different UL classification.

Temperature is often the most critical and overlooked factor in producing a control panel. TUTCO Farnam’s panels are rated to Operate in environments from 5C (41F) up to 104°F (40°C) in order to maintain the UL standard. That is the internal temperature and includes the heat coming off of the internal components. As the amperage of the controller increases, the components generate more and more heat.

Sharing information about your process and the environment your controller will operate in is essential. TUTCO Farnam works closely with customers to determine load profiles, peak temperatures, and environmental conditions so that each panel remains compliant—and reliable—under actual operating conditions.