Cool Touch™

Safe, High-Performance Air Heating with “Cool-to-the-Touch” Design for Industrial & Process Systems

• Max inlet temperature: 250 °F (121 °C)

• Max exhaust temperature: 1300 °F (704 °C)

• Efficient design reduces heat loss

• Cool Touch™ option is available for a variety of our Heat Torch sizes

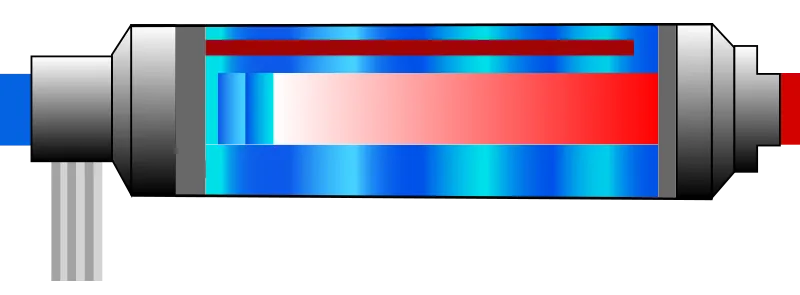

• Triple-pass construction keeps the heater body “cool to the touch” while delivering efficient, high-temperature airflow.

The Cool Touch™ line from TUTCO Farnam offers a safe, efficient, and powerful solution for industrial process air heating — combining high-temperature output with a user- and equipment-friendly external temperature profile. Thanks to a triple-pass heater design, hot air is internally routed so the skin of the heater remains cool. This design minimizes heat loss and reduces risk to personnel and adjacent components, while delivering stable, high-temperature airflow.

Cool Touch heaters are ideal for intermittent or continuous industrial use, where safety, temperature stability, and process reliability are critical. Available across multiple sizes and power levels, they can be deployed in a broad range of manufacturing, drying, curing, or air-handling applications — or integrated as custom-configured solutions.

Cool Touch™ 050

| MAX WATT: 500W | MAX INLET: 250ºF |

| MAX EXHAUST: 1300ºF | MIN SCFM: 1 |

| MAX SCFM: 10 | PSIG: 120* |

Cool Touch™150

| MAX WATT: 5000W | MAX INLET: 250ºF |

| MAX EXHAUST: 1300ºF | MIN SCFM: 4.8 |

| MAX SCFM: 70 | PSIG: 120* |

Cool Touch™ 200

| MAX WATT: 12500W | MAX INLET: 250ºF |

| MAX EXHAUST: 1300ºF | MIN SCFM: 9.6 |

| MAX SCFM: 100 | PSIG: 120* |

Key Features & Benefits

Safe, “Cool-to-the-Touch” Exterior

The triple-pass internal design isolates the heated air path from the external housing, safeguarding personnel and surrounding components from high surface temperatures — critical in tight or personnel-dense installations.

High-Temperature Air Output with Minimal Heat Loss

Despite the safe exterior, Cool Touch heaters deliver air exhaust up to 1300 °F (704 °C), making them suitable for demanding applications while optimizing thermal efficiency.

Wide Power & Flow Range

With options from 500 W to 12,500 W and flow capacities from a few SCFM up to 100 SCFM, Cool Touch heaters cover a broad spectrum — from low-flow lab setups to high-volume industrial processes.

Versatile Applications

Cool Touch heaters are built for multiple industrial use-cases: staking, curing, heat-shrinking, drying, sterilization, adhesive activation, air-knives, air-scrubbing, and other process air heating needs.

Durable Construction

Stainless-steel bodies, robust fittings, and a design rated for pressurized air (up to 120 PSIG) make Cool Touch suitable for demanding industrial environments.

Flexible Sizing and Configuration

Multiple size/power options across the family, plus the possibility to integrate control panels, thermocouples, and other accessories to form complete, turnkey heating solutions.

Why Choose TUTCO Farnam Cool Touch™ Heaters?

TUTCO Farnam has decades of engineering leadership in industrial electric air heating. Cool Touch™ heaters are a proven solution trusted by OEMs, system integrators, and R&D organizations worldwide. We combine:

- Precision-built heating elements

- Industry-leading temperature performance

- UL-recognized safety compliance

- Custom engineering support

- Fast response and reliable long-term operation

Advantages Over Conventional Air Heaters

Faster Thermal Response

The low-mass open-coil design delivers extremely fast heat-up and cool-down—far superior to cartridge, tubular, or immersion-style heating devices.

Cool to the Touch

Triple-pass construction keeps the heater body “cool to the touch” while delivering efficient, high-temperature airflow.

Compact Integration

The cylindrical form factor fits easily into existing machinery and directly replaces bulkier assemblies while improving performance.

System Flexibility

With multiple standard models and extensive customization available, Heat Torch can be adapted to specialized systems without redesigning major equipment components.

Applications

Cool Touch™ heaters are used in a wide range of industrial and laboratory environments that require focused, controlled heat that safeguards people and other components.

Automotive & Transportation

High-capacity staking, adhesive activation, and heat shrinking are widely used in automotive component assembly, wiring harness production, interior trim bonding, and plastics processing. Cool Touch™ heaters provide consistent high-temperature airflow while maintaining a safe exterior for operators working in close proximity.

Electronics & Consumer Devices

Precision processes such as adhesive activation, micro-staking, curing of coatings, and heat shrinking of sleeves or protective tubing are essential in electronics manufacturing. The stable, enclosed, cool-to-the-touch design helps protect sensitive components and ensures safe integration into compact automated lines.

Medical, Biotech & Laboratory Equipment

Sterilization, drying, adhesive activation, and controlled process heating are common requirements in medical device production, lab automation, and cleanroom environments. Cool Touch™ heaters enable these high-temperature processes while keeping external temperatures low, protecting equipment and personnel.

Packaging, Converting & Printing

Drying, curing, heat shrinking, and the use of heated air knives support high-speed production lines, label application, film processing, and structural package sealing. Cool Touch™ units deliver stable thermal output for continuous operation and uniform results across large production volumes.

Aerospace & Defense

Applications such as adhesive activation, precision curing, heat shrinking of harnesses, and controlled process heating support both production and MRO operations. The cool external housing allows safe installation near sensitive materials and instrumentation.

Industrial Manufacturing & Assembly

High-capacity staking, drying, curing, and adhesive activation play essential roles across general manufacturing, automated assembly, and thermal processing systems. Cool Touch™ heaters provide consistent, high-temperature airflow for demanding, continuous-duty operations.

Environmental Systems & Air Filtration

Air scrubbing and heated air-knife systems are common in environmental control units, VOC reduction systems, industrial filtration, and chemical-process ventilation. Heated airflow improves scrubbing efficiency and supports contaminant removal in airflow-dependent processes.

Food, Beverage & Sanitation

Sterilization, drying, and controlled heating processes are used in packaging, surface treatment, and sanitation systems. Cool Touch™ heaters supply clean, high-temperature air while preventing external surface temperatures from posing a risk in worker-dense environments.

Ready to Build Your Solution?

Request a Quote or Contact our Applications Engineers to learn how a Cool Touch™ heater can improve your process consistency, energy efficiency, and thermal performance.

Control Systems & Temperature Regulation

TUTCO Farnam offers a full range of control solutions engineered specifically for Cool Touch™ systems. Our control panels provide accurate, reliable temperature regulation and seamless integration with your process equipment.

Key Control Options

Closed-Loop PID Temperature Control

Maintains tight temperature tolerances across variable flow rates and dynamic operating conditions.

Solid-State Relay (SSR) Power Switching

Delivers silent, efficient power modulation with extended service life and high cycling durability.

Integrated Safety Monitoring

Control packages can include:

- Type K thermocouples

- High-limit thermal cutouts

- Fault indication

- Airflow/pressure safety interlocks

- Ground-fault and overload protection

PLC & Automation Integration

Panels can be configured for Ethernet/IP, Modbus, and custom industrial protocols, making it easy to incorporate a Cool Touch heater into automated production lines.

Single-Source System Responsibility

Ordering heater + controls from TUTCO Farnam ensures matched components, correct power sizing, and verified performance.

Frequently Asked Questions

Yes — Cool Touch heaters are designed for pressurized air or gas streams (rated to 120 PSIG) and are suitable for compressed-air, inert gas, or clean-air applications when proper materials and fittings are used.

Choose Cool Touch when safety, exterior temperature control, and high-temperature air output matter — ideal for mid-to-high temperature processes with possible human or component exposure.

Use Heat Torch when compact footprint, direct open-air heating, and minimum airflow conditions suit your needs (for small-scale, high-pressure, focused heating).

Use Flow Torch when you need very high airflow volumes at moderate-to-high temperatures and low pressure drop (for large-volume heating, ventilation, air-knife, or space heating applications).

250 °F (121 °C) maximum inlet air temperature.