Industrial Control Panel Communication Protocols

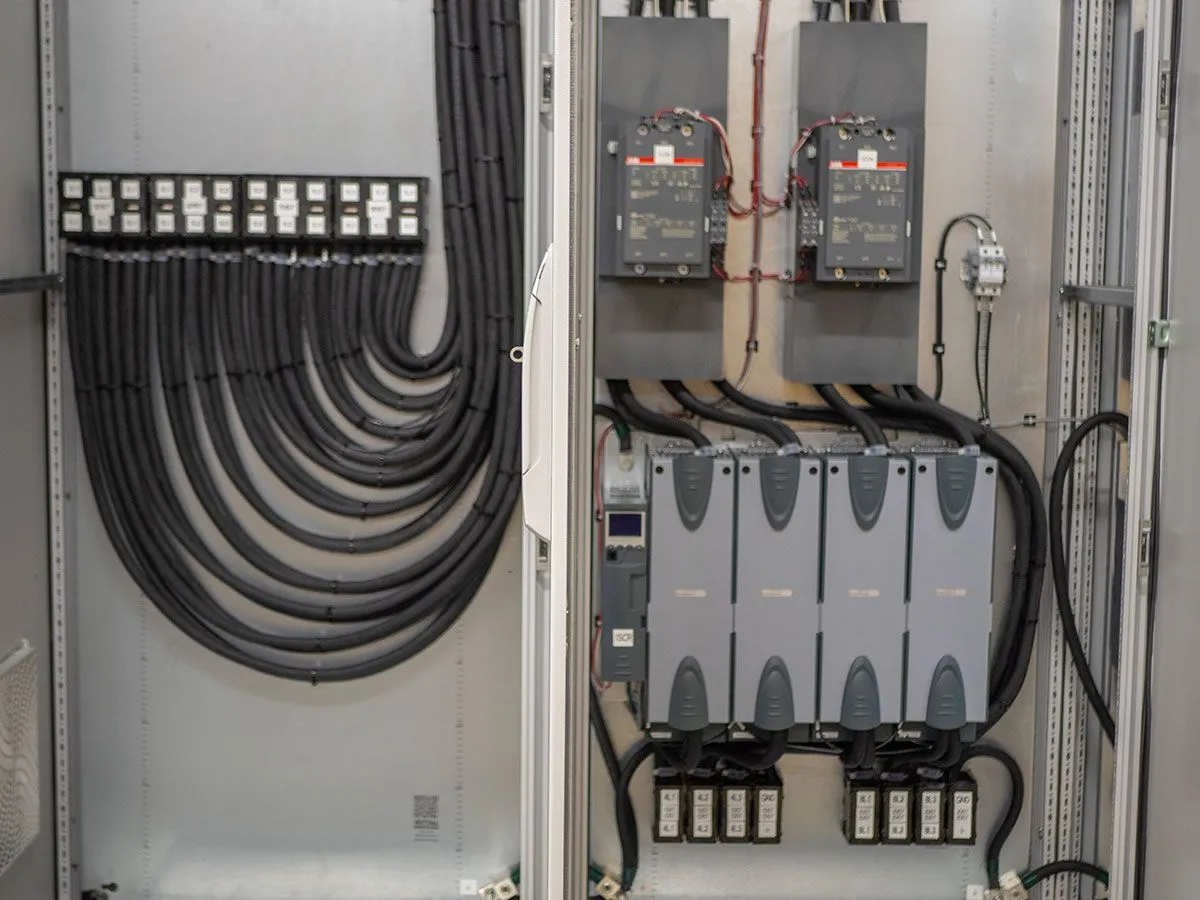

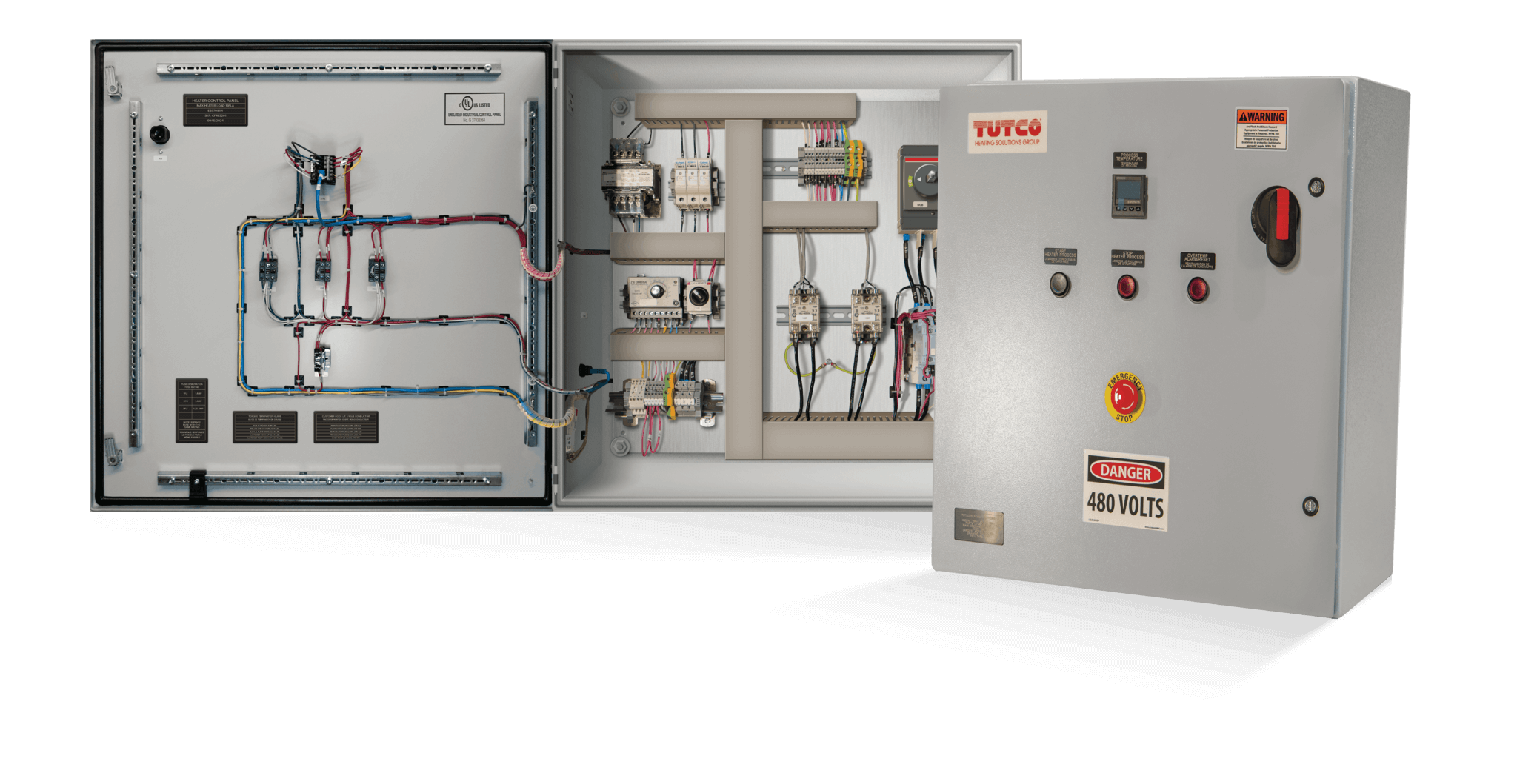

In today’s industrial environments, control panels can do a lot more than be an onf/off switch—they easily regulate, systematically initiate, and seamlessly integrate to communicate with a wide range of your system components where automation is desirable. At TUTCO Farnam, communication protocols can be engineered into every panel, ensuring reliable data exchange across diverse systems and networks.

In today’s industrial environments, control panels can do a lot more than be an onf/off switch—they easily regulate, systematically initiate, and seamlessly integrate to communicate with a wide range of your system components where automation is desirable. At TUTCO Farnam, communication protocols can be engineered into every panel, ensuring reliable data exchange across diverse systems and networks.

From controlling the heaters that TUTCO Farnam produces ensuring optimal performance in complex process heating applications to factory-floor automation. TUTCO Farnam’s custom control panels are designed to meet customer’s needs. Some of the most widely used industrial protocols, including EtherNet/IP, PROFINET, Modbus (RTU and TCP), and BACnet are just some examples of what we can offer.

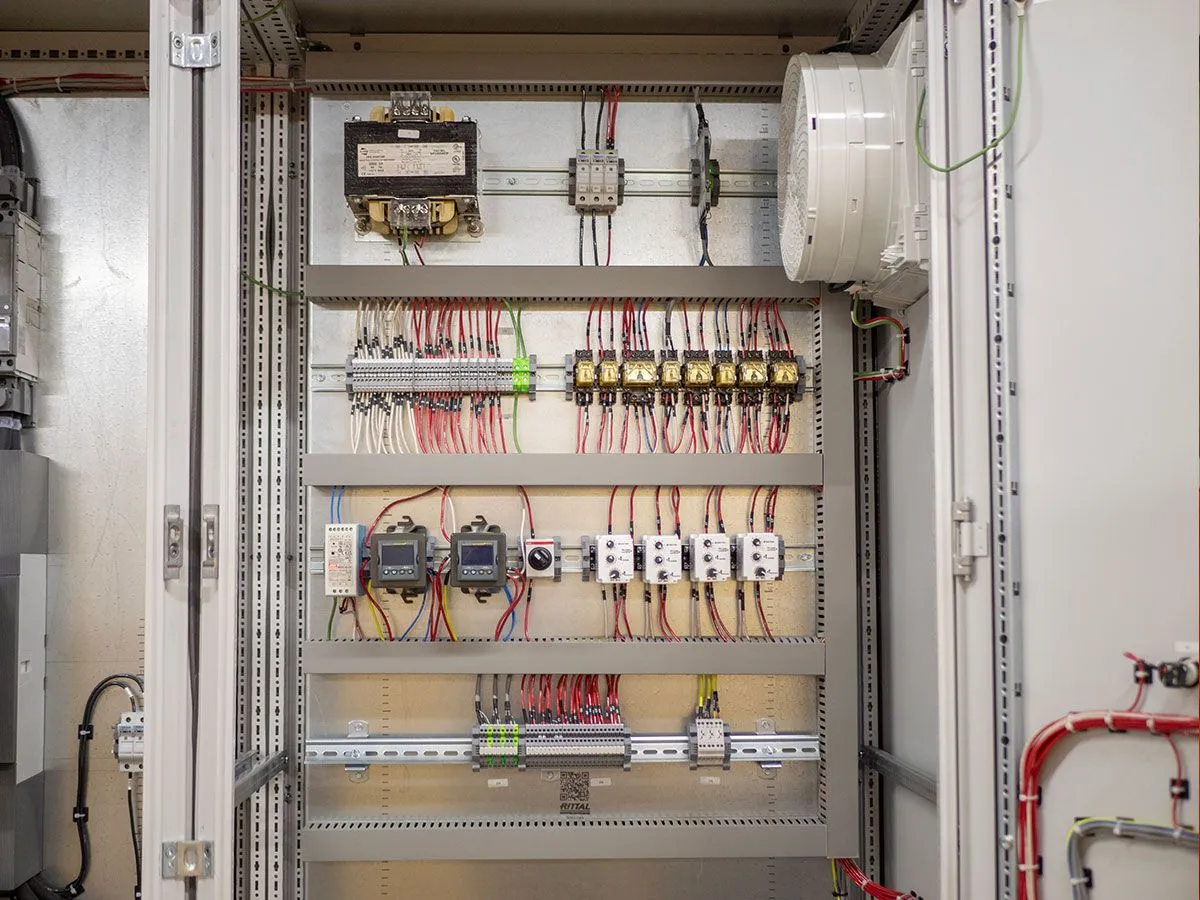

Whether the control system is Allen-Bradley-based—where EtherNet/IP is native—or a Siemens platform running PROFINET, TUTCO Farnam panels can be configured to integrate with any platform. Each panel is engineered with the end-user’s application in mind, allowing for fast, reliable communication between controllers, sensors, and any other needs you may have.

Industrial Automation

Modbus, one of the most common protocols in industrial automation, is also a key part of TUTCO Farnam’s offerings. With the ability to support industry standards of both simple wired RTU (Remove Terminal Unit) or networked based TCP (Transmission Control Protocol) Modbus communications, our panels can serve a broad range of legacy and modern systems alike. BACnet support extends the panel’s capabilities into the building automation sector, where HVAC and environmental systems also require precise, responsive control.

TUTCO Farnam supports a full range of communication mediums based on application needs and environmental constraints. Local area network connections are incorporated into our standard panel offering, while optional wireless integration enables remote monitoring, diagnostics, and support from virtually any location.

TUTCO Farnam enables process, manufacturing, and controls engineers to implement reliable control regardless of what the panel is controlling or the communication protocol. The company’s ability to support both standard and custom protocol configurations ensures that each panel is a precise fit for the customer’s control needs.